ABS is a popular and cost-effective 3D printing filament, favored for many 3D printing projects. However, most 3D printers have a drawback: their printed parts lack the smooth finish of injection-molded counterparts. They exhibit a matte, rough surface with visible layer lines, regardless of the chosen layer height.

To achieve a smoother surface, post-processing is necessary. ABS acetone smoothing is one of the most popular 3D printing surface finishing solutions. While other thermoplastics can be dissolved using different solvents, none match the effectiveness of acetone on ABS. However, it’s crucial to exercise caution when smoothing 3D printed ABS plastic parts.

This article provides a stepwise guide to performing ABS smoothing, Detailing the various safety measures. You will also learn tips for achieving the best possible finish as well as alternative post-processing techniques.

What Is ABS Acetone Smoothing?

ABS acetone smoothing is a technique used for post-processing ABS 3D printed filament. It effectively eliminates layer lines by melting them with acetone. The process involves exposing untreated 3D printed ABS plastic parts to acetone vapors, causing the individual print layers to fuse together. This results in a glossy surface finish with no visible lines.

What Is Acetone?

Acetone is a transparent organic liquid renowned for its versatility as a chemical solvent, capable of dissolving both polar and nonpolar substances. What sets acetone apart is its unique ability to dissolve both polar and nonpolar substances, a feature lacking in many other solvents. This versatility arises from acetone’s chemical composition, which combines polar and nonpolar elements. Consequently, acetone finds applications with both organic and inorganic materials.

Furthermore, acetone is miscible with water, meaning it can seamlessly mix with water in any proportion. This property makes it valuable for aiding in the dissolution of various chemicals in diverse settings. Despite its organic nature, acetone remains non-toxic, adding to its broad utility in numerous fields.

How Acetone Interacts with ABS Plastic

Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer created by polymerizing styrene and acrylonitrile alongside polybutadiene. As with all polymers, ABS exhibits resistance to certain substances while being susceptible to others.

Regarding its chemical composition and smoothing, ABS has a notable trait of being soluble in various compounds. These compounds include esters, chloroform, ethylene dichloride, and certain ketones, including acetone. Notably, chloroform and ethylene dichloride are hazardous and require rigorous safety precautions. On the other hand, acetone is a milder and more manageable option for non-controlled environments.

From a chemical standpoint, acetone dissolves ABS because the thermoplastic is soluble in ketones. This results in the ABS (the solute) dissolving into the acetone (the solvent), creating a mixture or solution (slurry) on the plastic’s surface. Practically, applying a small quantity of acetone to a 3D-printed ABS part leads to the surface dissolving.

Why Should You Acetone Smooth Your ABS Prints?

When done systematically, ABS acetone smoothing can selectively remove enough ABS to eliminate imperfections like layer lines, yielding a smoother component. Some researchers have even proposed that acetone smoothing can enhance the strength of ABS parts by promoting better interlayer adhesion. Here is why you should acetone smooth your ABS 3D prints.

Achieving a Glossy Finish

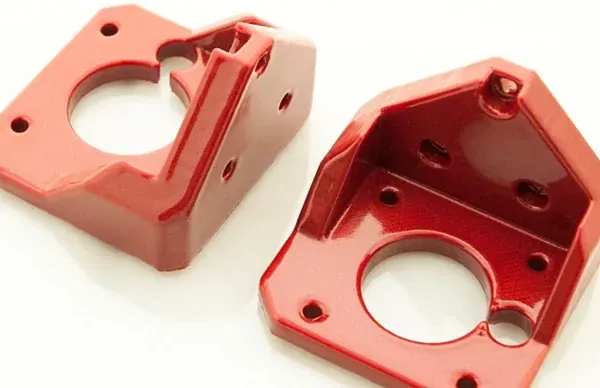

Smoothing ABS parts is a method to eliminate visible lines and transform the surface texture from matte to glossy. Using acetone, the ABS part undergoes a near-dissolution process, causing the layers to bond and resulting in a shiny surface appearance. The outcome is a 3D print that is smooth, shiny, and professionally finished.

Glossy surfaces are particularly appealing for certain types of prints, such as models, figures, busts, and decorative pieces. Additionally, when the filament matches the desired color, there’s no need for additional painting. The enhanced appearance of glossy parts also adds versatility, making 3D-printed ABS components suitable for various applications.

Removing Layer Lines and Imperfections

Some 3D printing processes often result in visible layer lines on parts due to the movement from one layer to another along the Z-axis. These layer lines are especially noticeable with larger layer heights and curved designs. Acetone plays a key role in the smoothing process.

When applied to the 3D-printed ABS part, acetone smoothens the surface and merges the gaps between layers. This results in a part with no discernible lines resembling an injection-molded product. Additionally, the absence of open gaps reduces leakage. This makes it suitable for printing items like vases, containers, part boxes, etc.