Injection molding is a popular manufacturing method for plastic parts. This technology is efficient for high-volume production, maintaining repeatability and cost-effectiveness. However, any deviation in tooling, process variables, and raw material quality causes various defects in molded parts. A flow mark in injection molding is one major defect that influences the finish and aesthetic appeal.

Understanding the nature of flow marks can help you produce defect-free parts exact to your design specifications. So, let’s discuss types of flow marks, their causes, and prevention strategies in detail.

What is a Flow Mark in Injection Molding?

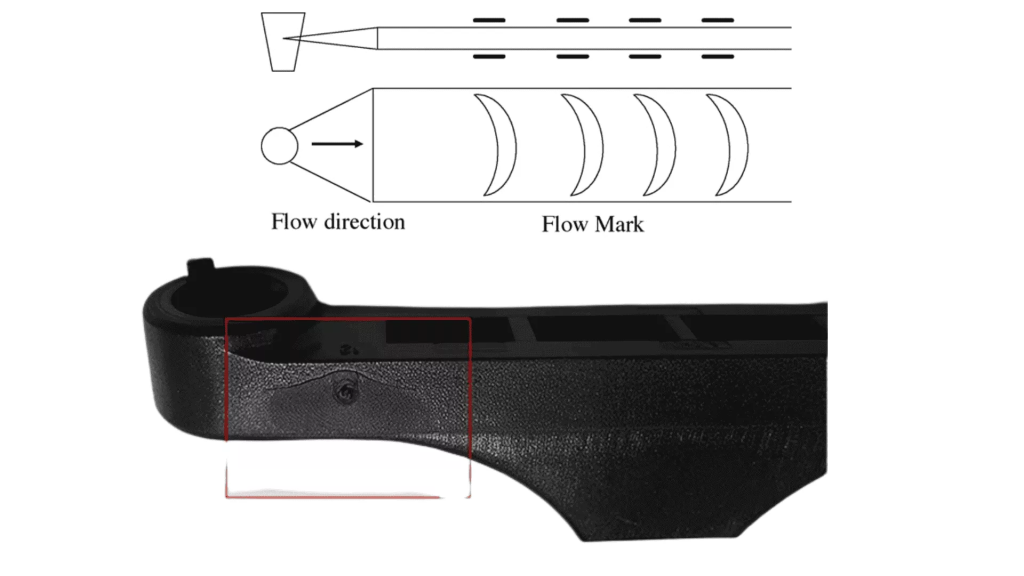

Flow marks, also known as flow lines, are the wavy lines, streaks, or patterns developed on the surface of the plastic material during the injection molding process. Although it does not affect the structural integrity of the material, it is a cosmetic defect that can reduce the aesthetic appeal of the product, resulting in lower perceived quality and consumer acceptability.

The flow lines usually follow the direction of melt flow inside the cavity and are commonly found near gates or around sharp corners. It indicates poor process control, as it is caused by various factors leading to uneven flow patterns of the melt plastic, resulting in inconsistent cooling.

Types of Injection Molding Flow Marks

These marks on the surface of molded parts/products can be categorized into different types based on their appearance and formation mechanism.

Let’s discuss wave, jetting, radiation lines, periodic bands, weld lines, and other types of flow marks in injection molding.

Wave Flow Marks

It is a wavy streak along the flow direction of the feeding charge. Faster cooling and solidification of the outer layer while the inner layer flows inside the mold, resulting from sudden cooling at the walls of the mold or non-uniform flow velocity, cause this type of flow mark to appear. These types of flow marks are commonly found on large, flat, and glossy surfaces, including electronic casing and automotive interior panels.

Jetting Marks

It is a small, irregular snake-like streak leading from the injection gate. It happens when the flow of the fluid is too high and gets turbulent, where the charge does not get enough time to spread evenly. The marks resemble the squirting of the molten charge from the gate. It is typically found in components with narrow gates followed by wide openings of the cavity, such as connectors, automotive bumpers, and precision components.