Among several metal parts manufacturing processes, metal casting is known for its capability of complex shapes, material versatility, and high-volume production. But what is casting exactly? It is the process of converting raw metal and alloys into desired functional parts by pouring their molten form into a pre-designed die cavity, followed by solidification. Meanwhile, the die cavity is the mirror of the intended part geometry.

You can find many types of casting techniques, each with unique features and benefits; sand casting, die, and invest casting are a few. However, which methods to use depends on the raw material type and specifications of the designed parts. This article will discuss the casting process, techniques, compatible metals and alloys, advantages, and disadvantages to provide a comprehensive overview.

What Is Casting?

It refers to any metal and alloy part made when molten metal forms a geometry on solidification. The liquid metal takes up the geometry of the cavity containing it. After pouring, material flows across each corner inside the cavity (die or mold) and captures each detail. Then, the part is ejected for a die or mold cavity.

If we look into its history, casting can be traced back to seven thousand years (around 3200 BC) in ancient Mesopotamia and China to convert copper into different useful items. Then, sand casting became one of the most prominent fabrication ways of tools and cooking wares after 645 BC.

In the modern manufacturing era, the metal casting process is integrated into all industries as its capabilities develop continuously. It can make precise and complex components at low prices, especially in high-volume runs. The die, mold, or other forms of cavities can produce thousands to millions of identical parts. However, sand and investment molds are only usable for a single time, which is economical for prototyping projects. Additionally, the cast parts preserve the original mechanical and physical properties.

How Does Casting Work?

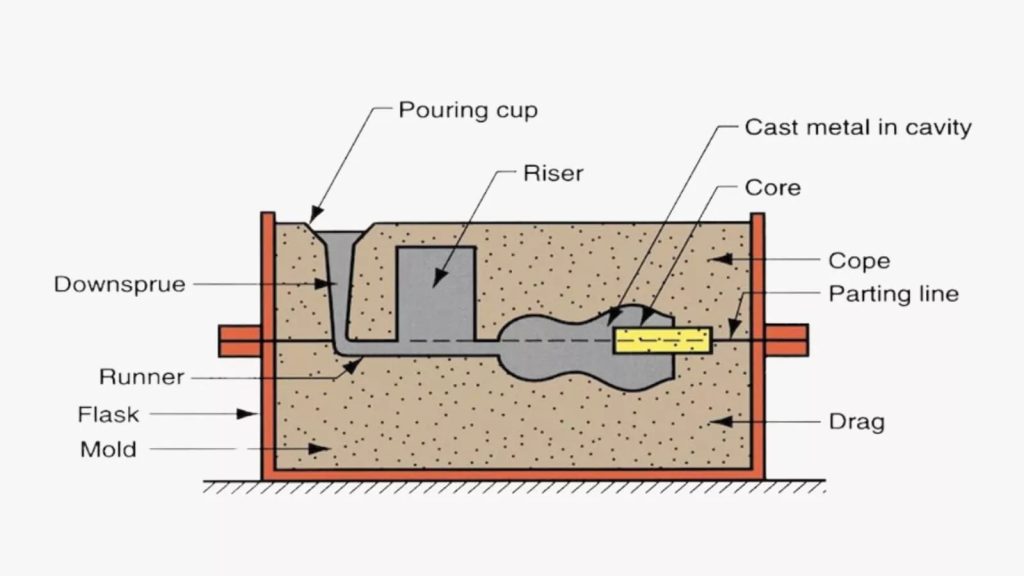

The casting or cast molding process involves two different types of approaches, using a pattern for cavity and precise die or mold that can withstand numerous cycles. The following are some terminologies related to its working;

- Pattern: It is the full-sized replicate of the desired part made with metal, plastic, or wood used in shaping the mold.

- Core and Cavity: Cavity refers to a hollow section that outlines the cast part’s external features, while the core creates internal features, such as holes and channels.

- Gating System: Channels that guide and control metal liquid flow from the pouring furnace to the cavity. It includes components like sprues, runners, and gates.

- Riser: A reservoir in the mold that feeds molten metal to the casting to compensate for shrinkage during solidification, ensuring the cast remains free from cavities and defects.

Next, let’s elaborate step by step on how casting works.

Step 1: Creating the Mold Cavity

A pattern is necessary to create the cavity since it acts as the body mass of the desired shape. The replica or pattern can be made with wood, plastic, or wax. Subsequently, some considerations are essential in pattern design and fabrication, such as size accommodation for shrinkage allowance, draft angles for easy removal, core prints for hollow sections, etc.

After creating the pattern, it is placed in a molding box surrounded by mold material like sand or ceramic. Then, it captures the shape and leaves the cavity while ejecting. However, the permanent mold cavities are made with advanced manufacturing techniques like CNC and EDM machining stainless steel or aluminum.

Step 2: Pouring the Molten Material

First, the material melting involves an electric arc, induction, or crucible, depending on the casting size. For example, a large-size casting requires large furnaces to melt the raw material and small ladles to transfer before pouring.

Pouring is done by manually handling the crucible or mechanical and hydraulic tipping. However, continuous casting machines can automatically pour molten material into pouring basing as molds move along a production line. The temperature varies based on the melting point of the casting material. For instance, the stainless steel casting reaches as high as 1000℃-1250℃. Next, sprue and gating systems guide the liquid material to the cavity.

Step 3: Cooling and Solidifying

Once the liquid metal captures details of all cavities, it is left to cool and solidify for a specific time period. The cooling system might involve channels and passages to control the cooling rate. Meanwhile, the cooling time depends on the cast part size, intricacies, and material type.

During solidification, tiny solid particles called nuclei come together and start crystal growth, ultimately forming the grain structure of the respective material. This mechanism allows the regaining of the original properties.

Step 4: Removing the Cast Product

Finally, the product is removed from the mold. If the mold is expandable( sand or investment casting), the operator or mechanical system breaks it to eject the final parts. On the other hand, ejection mechanisms remove the metal cast products in the case of reusable molds and die. Then, cleaning and post-processing ensure the dimensional accuracy and finish quality.

Now we know what is casting and its fundamental working mechanism, let’s discuss what the casting types are.

Different Types of Casting Methods

As industries continuously look for more precise and complex cast parts, metal-casting technologies are parallelly developing new methods and techniques. You can find numerous types of casting methods, such as sand or silica casting and die casting methods, each with some unique capabilities. The comparative analysis(process, benefits, and applications) of these techniques can help you decide which one is the best fit for your project.

The following are the common casting methods in manufacturing.

Sand Casting

The sand mold casting method uses tightly packed fine silica-based materials or sand grains to make the mold. The mold involves two sections; cope and drag (upper and lower half). Meanwhile, the molten metal is poured into the cavity formed by these two sections. This mechanism also ensures precise alignment, easy handling, complex shapes, and efficient gating.

Benefits:

- The mold-making and casting process is simple and highly cost-effective in terms of tooling cost.

- Sand mold casting is compatible with almost every alloy, ferrous and non-ferrous both.

- Versatility in shape and size. It can cast parts that are 200+ tons in weight.

- Although the dimension accuracy is low, post-processing is straightforward and takes less time.

Applications: Pistons, bushings, electronic components, valves, bearings, engine crankcases, plant machinery, etc.

Investment Casting

The investment mold casting process is relatively more complex than sand cast. It involves preparing a mold using wax patterns connected in a central wax sprue. Then, refractory material like ceramic surrounds this network. Next, heating the mold melts the wax patterns inside the refractory and leaves the cavity with a smooth finish, the reason why it is also known as lost wax castings. Then, liquid is poured into this cavity, and the mold is broken to remove the parts after solidification is complete.

Benefits:

- Using a wax pattern allows the making of hollow sections, undercuts, and internal channels without inserting the core.

- Fined grain structure and better surface finish.

- Good dimensional accuracy (± 0.1mm)

- Thin-walled parts with complex geometries

Applications: Military and aircraft components like engine parts, industrial plant components, automotive engine and exhaust systems, medical implants and instruments, etc.

Die Casting

This casting uses permanent molds ( called die) made from strong materials like hardened tool steel. It is typically used for materials like zinc, aluminum, copper, and tin. The die casting process includes melting the raw material in a furnace, which might or might not be attached to the casting machine. Then, the hydraulic plunger or injection mechanism transfers the liquid into the die. Meanwhile, the pressure can reach up to 25000 psi.

Benefits:

- Tight tolerances and consistency across production cycles

- Less requirement for post-processing operations

- Cost-effective for high-volume production

Applications: It has a broad application spectrum; automotive parts, aircraft turbine blades and airframes, electrical housing, industrial items, machine tools, and household appliances are a few examples.

Centrifugal Casting

The centrifugal or rotatory cast method uses a cylindrical mold that rotates around its axis, and liquid metal is poured into this rotating mold. The centrifugal force pushes the poured metal against the mold walls, forming a uniform layer. Then, solidification gives the shape of the mold with a specific thickness.

Benefits:

- Free from porosity due to continuous feeding of metal liquid

- As centrifugal casting parts solidify inwardly, there is minimal risk of gas pockets and shrinkage cavities.

- The absence of a risner reduces the material consumption during the pouring stage.

- A dense and homogenous structure of grains.

Applications: This casting manufacturing is predominantly used to manufacture symmetrical items, such as hollow cylinders, shaft sleeves, pipes and tubes, pressure vessels, disk shapes, etc.

Low-Pressure Casting

The pressure of the pouring or pressurized furnace attached to the casting machine typically consists of a pressure of 0.02 to 0.07 Mpa. The pouring furnace remains below the cast, forces the metal liquid above with the riser tube, and then transfers it into the cavity. The continuous pressure is necessary to fill the cavity. Once it is filled, the cooling channels cool the mold in a controlled manner until complete solidification is achieved.

Benefits:

- The low pressure allows for precise control of filling and eliminates the turbulence, reducing defects like porosity and shrinkage.

- High accuracy and detailed casting.

- The low-pressure casting process is compatible with various non-ferrous materials like aluminum alloys.

- The smooth filling also enables the casting of sharp corners and intricate geometries.

Applications: Cylinder hub and frame, wheel hubs, kitchenwares, custom hollow and complex profiles, fittings, electronic appliance components, etc.

Gravity Die Casting

Pressure injection or plunger mechanism is unnecessary for the metal pouring during the gravity die-casting process. It involves transferring the material from the furnace or ladle into the mold using gravity. No other forces influence the flow until the filling is complete. Furthermore, it mainly accommodates non-ferrous alloys with low melting points, such as copper, zinc, aluminum, and magnesium.

Benefits:

- Deine structure, better mechanical properties, and surface finish.

- The absence of pressure flow provides minimal porosity in the final parts.

- It has more straightforward tooling than other permanent molds due to no need for an injection mechanism.

Applications: Gravity die casting offers diverse applications across many industries, including automotive components, industrial machinery parts, aerospace engine and housing elements, decorative items, parts for household appliances, and more.

Vacuum Die Casting

As the name suggests, the vacuum casting process molds the molten states of metal or plastics into the vacuum. Generally, a pump or similar mechanism removes all the air inside the mold during the process.

Silicone molds, like polyurethane, are used for rubber and plastic molding. However, other types of mold and dies are also applicable to vacuum-cast different materials. Additionally, this casting manufacturing mimics some characteristics of the injection molding technique. This vacuum casting strategy is also adaptable to standard die casting to minimize the risk of air trapping.

Benefits:

- High precision and accuracy, especially for projects where molds are 3D printed.

- Fine cast with intricate details

- It eliminates the pore formation risk inside the cast metal.

- Good capability of casting the parts with thinner walls

Applications: Functional plastic prototypes, medical implants and prosthetics, consumer goods, automotive body panels and other components, food processing components, etc.

Squeezing Die Casting

This method creates the parts by pressing the liquid and semi-solid material inside the die. First, the liquid metal fills the heated open die, then the upper parts close it and give pressure through the attached hydraulic plate or other suitable mechanisms. The parts solidify under pressure and provide better mechanical property characteristics. Furthermore, it is also known as liquid-metal forging.

Two types of squeezing die casting exist: direct and indirect. In the direct process, the molten metal fills the die, and the upper half closes the die. On the other hand, indirect types first inject the molten metal into the cavity, followed by applying high pressure via a punch or plunger.

Benefits:

- Excellent surface texture and minimal porosity.

- Quick production cycles.

- The squeeze casting produces accurate (near-net-shape) parts.

- Quick heat transfer during pressing results in fine microstructures.

Applications: High-strength automotive components like chassis and engine brackets, aerospace parts, industrial gears and hydraulic components, medical device parts, etc.

Lost Foam Casting

The reason behind the name “lost foam” is that a polystyrene foam pattern of the desired part is responsible for producing the final shape. The pattern is placed inside the refractory materials, which melt away after pouring the liquid material and provide the shape after solidification. Then, breaking the mold reveals the part.

Benefits:

- Intricate geometries with excellent surface quality and minimal post-machining requirements.

- Lost foam casting is compatible with various materials, including iron, stainless steel, aluminum, and copper.

- It simplifies manufacturing, reducing time, labor, and material waste.

Applications: Rapid prototypes for testing, automotive cylinder heads and weldments, pipe fittings, valves, pump enclosures, etc.

Continual Casting

The continual casting includes continuous pouring, solidification, and part removal in a production line. The setup and process involve a ladle or furnace, and material flows to the mold cavity, passing a control system. Subsequently, a cooling mechanism ( water channels) in the mold reduces the temperature quickly. So, while leaving the mold parts significantly cooler, further water spray brings them to room temperature.

Benefits:

- It is a straightforward process as continual casting does not require a runner, sprue, and riser.

- 100 % rating yield, no material wastage.

- The automation of continual cast boosts efficiency and productivity.

Applications: Parts with consistent profiles, such as beams, columns, rods, strips, tubes, etc.