Experience industrial 3D printing powered by precision and innovation. Upload your design, get a quote in seconds, and receive your custom parts with tight tolerances and rapid turnaround — all under globally recognized ISO certifications.

Experience precision 3D printing tailored to your exact requirements. From rapid prototyping to full-scale production, we deliver high-quality custom parts with exceptional accuracy and speed. Using advanced technologies such as SLA, SLS, HP MJF, and SLM, we produce detailed components with tolerances as fine as ±0.2 mm. Partner with our 3D printing specialists for consistent, high-resolution results that bring your designs to life.

SLA utilizes a laser to cure liquid resin into solid parts with high precision and smooth surfaces. Ideal for detailed prototypes

HP MJF uses a fusing agent and heat to create strong, functional parts with fine details and excellent mechanical properties.

SLS fuses powdered material layer by layer using a laser, producing robust and durable parts. It’s complex geometries applications.

SLM melts metal powders with a laser to create high-strength, intricate metal parts. Ideal for many parts

Our post-processing solutions refine your 3D printed parts for both performance and presentation. Through techniques like sanding, polishing, coating, and coloring, we deliver smooth surfaces, enhanced strength, and professional-grade finishes. Ideal for display models, end-use parts, and functional components that demand precision and visual appeal.

Ideal for functional prototypes or internal components without aesthetic requirements.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

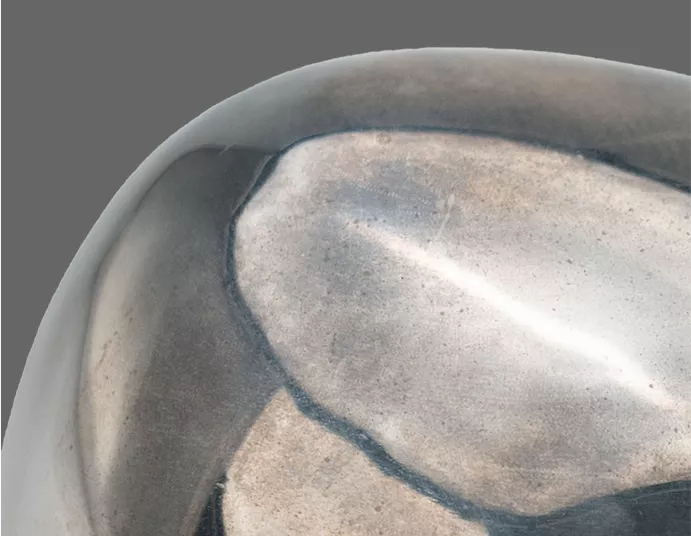

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

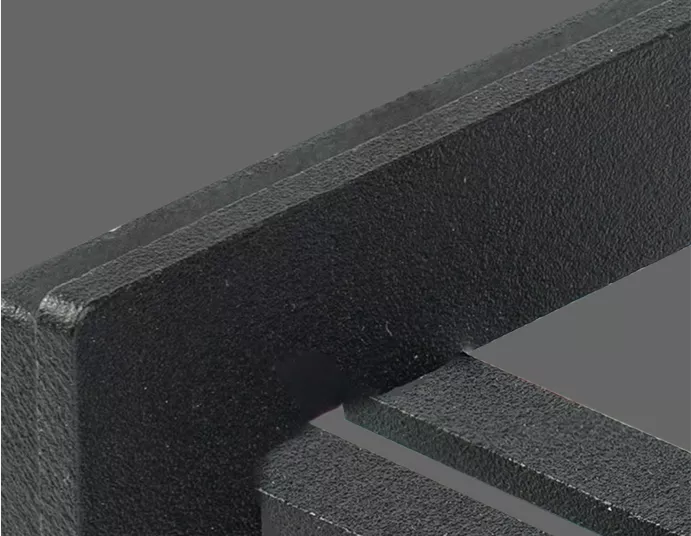

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

3D printing, also known as additive manufacturing, is an innovative process that builds three-dimensional objects directly from digital designs. By adding material layer by layer, it enables the creation of complex shapes and fine details that traditional methods can’t easily achieve. Unlike subtractive manufacturing, which removes material from a solid block, 3D printing minimizes waste and maximizes design freedom.

This technology is widely used across industries — from prototyping and product development to medical, automotive, and aerospace applications — offering unmatched flexibility, speed, and cost efficiency in modern manufacturing.

3D printing offers numerous benefits over traditional manufacturing methods:

3D printing supports a wide range of applications across industries and use cases:

We can produce parts with tolerances as fine as ±0.2 mm, depending on the material and printing technology used.

Lead times vary by size, complexity, and technology, but we can deliver high-quality parts in as fast as 1 day for most projects.

Our 3D printers accommodate a wide range of part sizes. For exact maximum dimensions, please consult our design guidelines.

We accept standard 3D design files including STL, OBJ, STEP, and IGES to ensure compatibility with our printing systems.

Choosing the right technology depends on your material, precision, surface finish, and production volume requirements. Our experts can help recommend the best option for your project.