Our state-of-the-art 5-axis CNC machines move along multiple axes simultaneously, enabling the production of highly intricate and precise components in a single setup. From aerospace and automotive to medical and high-tech industries, we deliver complex geometries, angled features, and multi-faceted designs with unmatched accuracy, speed, and surface finish. Reduce setup times, improve efficiency, and achieve flawless results with every part — no matter how challenging the design.

Experience advanced multi-axis machining for highly intricate and complex components.

Our 5-axis CNC machines enable simultaneous movement along five axes, producing angled surfaces, multi-faceted designs, and intricate geometries in a single setup. Ideal for aerospace, automotive, medical, and high-tech industries, delivering unmatched accuracy, efficiency, and superior surface finishes for every part.

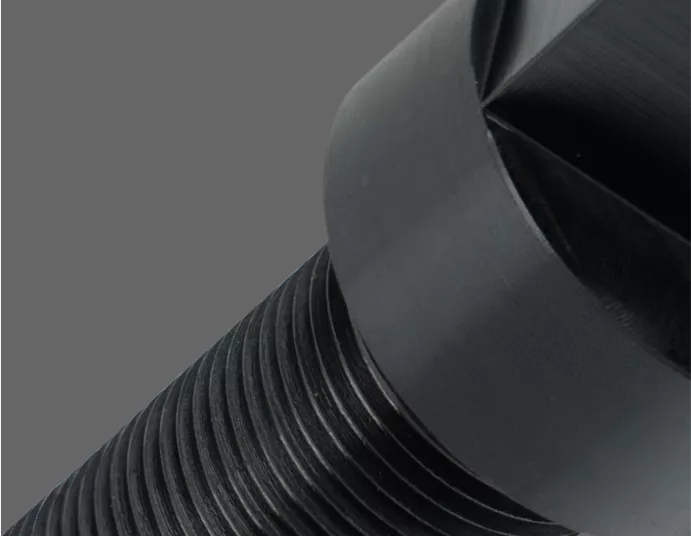

5-Axis CNC machining is an advanced manufacturing process where the cutting tool moves along five different axes simultaneously. Unlike traditional 3-axis or 4-axis machines, this capability allows the tool to approach the workpiece from virtually any angle, making it possible to produce highly complex shapes in a single setup.

The process begins with a digital design, usually created in CAD software. The design is converted into a CNC program that guides the machine’s movements along the X, Y, Z, and two rotational axes.

The workpiece is securely fixed to the machine table, while the cutting tool rotates at high speed, following the programmed path with exceptional precision.

This simultaneous multi-axis movement reduces the need for multiple setups, shortens production time, and ensures superior accuracy, surface finish, and consistency.

With an extensive list of surface finishes available, RapidDirect can enhance the surface quality of your 5-axis machined parts. Applying these finishes help improve the appearance of the components, their surface roughness, hardness, corrosion resistance, and more. They also hide visible tool marks on the products’ surfaces.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

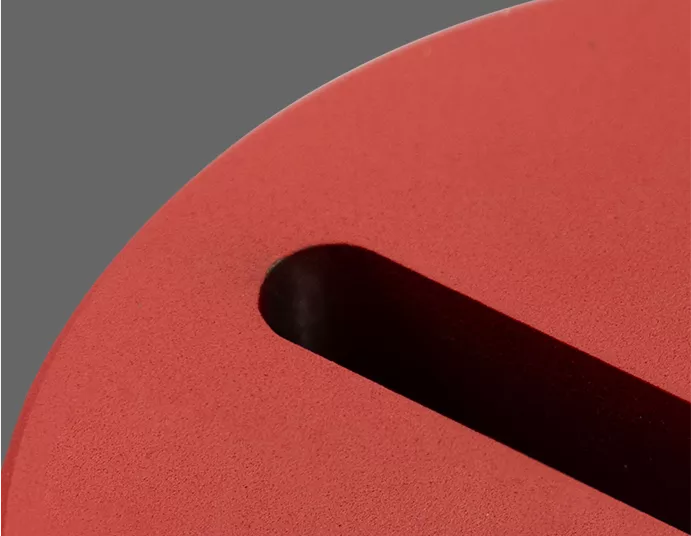

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

5-Axis CNC machining is an advanced manufacturing process where the cutting tool moves along five different axes simultaneously.

Unlike traditional 3-axis or 4-axis machines, this capability allows the tool to approach the workpiece from virtually any angle, making it possible to produce highly complex shapes in a single setup.

The process begins with a digital design, usually created in CAD software. The design is converted into a CNC program that guides the machine’s movements along the X, Y, Z, and two rotational axes.

The workpiece is securely fixed to the machine table, while the cutting tool rotates at high speed, following the programmed path with exceptional precision.

This simultaneous multi-axis movement reduces the need for multiple setups, shortens production time, and ensures superior accuracy, surface finish, and consistency.

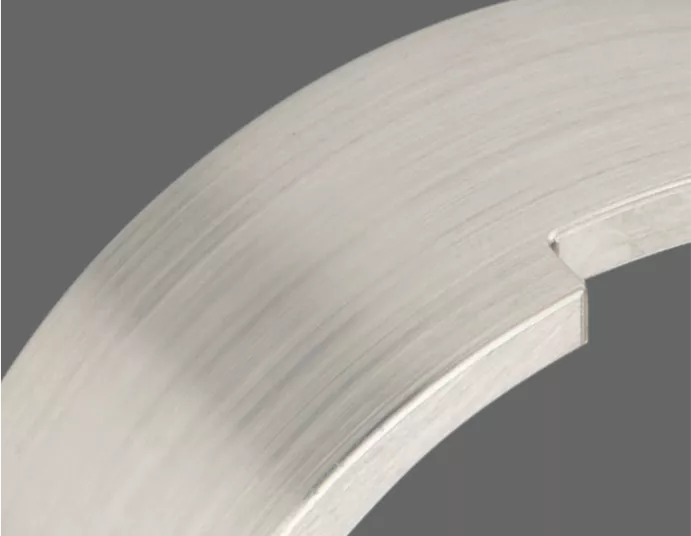

5-Axis CNC machining is ideal for producing angled surfaces, contoured geometries, and intricate features, making it essential in industries such as aerospace, automotive, medical devices, and high-tech components.

Achieve complex, multi-faceted parts with unmatched precision, efficiency, reduced setups, and superior surface finishes.

High-quality components for aerospace, automotive, medical, and high-tech sectors.

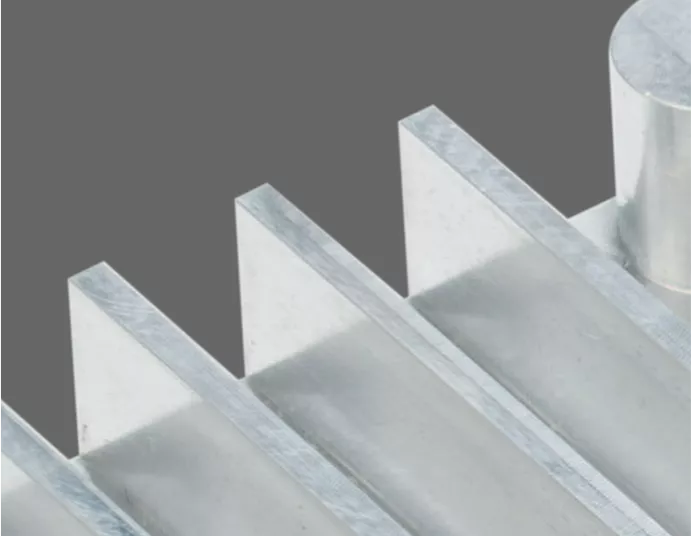

Easily produce threads, grooves, tapers, and other intricate geometries in a single setup for consistent results.

Delivering precision and reliability across milling, turning, and multi-axis operations.

Experience fast, precise, and continuous 5-axis CNC machining with superior surface finishes.

Our 5-axis machining centers move all five axes simultaneously without stopping, allowing smooth transitions and intricate contours in a single setup.

With intelligent programming and advanced machine control, we achieve highly efficient operations, reduce cycle times, and maintain exceptional accuracy across complex geometries.

Leverage 3+2 axis machining for applications requiring precise orientation and rigid cutting.

This method positions the part at a fixed angle while the three axes perform traditional machining, using shorter, stronger tools for enhanced stability.

It allows you to produce complex parts with tight tolerances efficiently, reducing costs and maintaining quality across smaller production runs.

Get answers to the most common questions about CNC machines, capabilities, and applications.

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to precisely remove material from a workpiece to create custom parts. It’s ideal for producing both prototypes and high-volume production parts with consistent accuracy.

It enables intricate part designs, reduces setup times, improves surface finishes, and increases overall precision.

Bludeek provides CNC milling, CNC turning, EDM, surface grinding, and assembly. We also offer molding and fabrication services for complete project support.

Common industries include aerospace, automotive, medical devices, high-tech components, and defense, where precision and complex geometries are required.

Yes, simultaneous multi-axis movement reduces multiple setups, speeds up production, and ensures accurate, high-quality parts in less time.

5-axis machines can handle metals, plastics, composites, and exotic materials, depending on tooling and machine specifications.

Absolutely! They are ideal for prototypes, low-volume production, and complex parts requiring tight tolerances and intricate designs.