Precision. Performance. Delivered Fast.

Achieve unmatched quality with our high-performance custom aluminum extrusions — engineered to ±0.1mm accuracy and delivered in as fast as 7 days. Whether you need complex profiles, tight tolerances, or durable finishes, we provide end-to-end solutions from design to production.

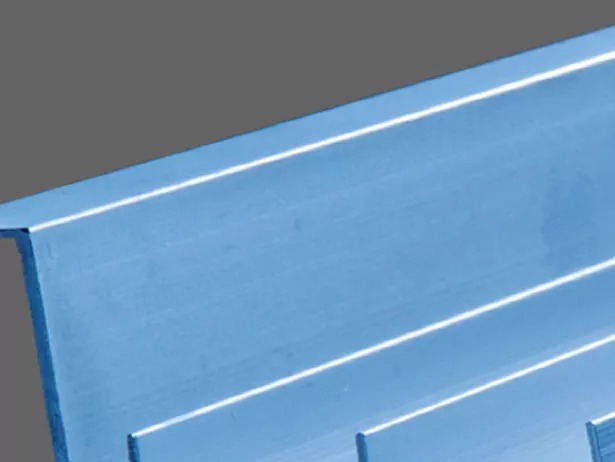

We offer custom aluminum extrusion services for prototypes and low-volume production, delivering high-quality extruded profiles with precise cross-sections and superior finish.

Our advanced manufacturing facilities include 70 extrusion press lines ranging from 600 tons to 3800 tons, capable of handling extrusions of various sizes, complexities, and quantities. All production is carried out in ISO 9001:2015 certified factories, ensuring consistent quality and performance.

Each aluminum extrusion is custom-made to meet specific shapes, design requirements, and applications across multiple industries, including:

Construction and Architecture – windows, doors, curtain walls, canopies

Automotive and Transportation

Electrical and Electronics

Consumer Products – light fixtures, sun shades, handrail systems

Our extrusions provide precision, durability, and design flexibility, making them ideal for a wide range of structural and decorative applications.

When standard profiles don’t meet your requirements for function, cost, or design, custom aluminum extrusions offer the perfect solution. Our fully customized extrusion services let you define every detail — including shape, color, surface finish, and material — to match your specific project needs.

Each design is carefully reviewed to ensure feasibility, precision, and performance, with optimized processes that deliver high-quality results and short lead times.

We support a wide range of custom aluminum profile types, such as:

For projects that require basic strength, shape, and functionality, standard aluminum extrusions provide a fast, cost-effective, and reliable solution. A wide selection of commonly used profiles is available to suit a variety of general applications.

Surface finishes protect extruded aluminum parts from corrosion and wear while improvding appearance. View RapidDirect’s finishing methods listed below. And we’re happy to discuss additional options to meet your specific requirements.

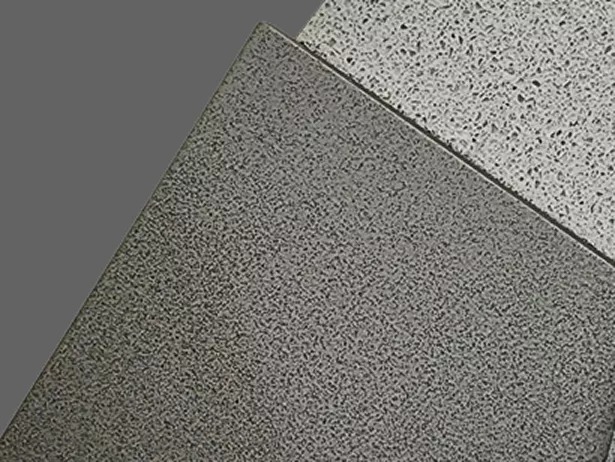

Forms a durable oxide layer that enhances corrosion resistance and provides electrical insulation. Available in natural, black, and various color finishes — ideal for architectural, decorative, and electronic applications.

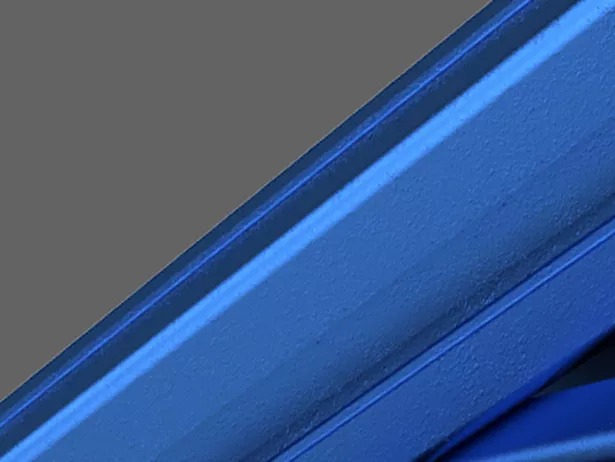

Applies a dry powder that is baked onto the aluminum surface, creating a tough, vibrant, and long-lasting finish. Resistant to scratches, UV exposure, and chemicals — perfect for outdoor and decorative products.

Uses an electric current to evenly deposit paint on complex or detailed shapes. Delivers a smooth, uniform finish with excellent corrosion protection, commonly used in automotive and architectural components.

A mechanical brushing process produces a linear grain texture that minimizes the appearance of scratches and fingerprints. Often chosen for consumer electronics, appliances, and architectural trims for a premium metallic look.

Applies liquid paint for flexible color selection at a lower cost. Well-suited for prototypes, small production runs, or projects where precise color matching is required.

Applies durable inks to print logos, text, or graphics directly on aluminum surfaces. Ideal for control panels, signage, nameplates, and branded components.

Uses a focused laser beam to etch permanent markings, serial numbers, or detailed designs. Delivers clean, precise, and high-contrast results for identification and decorative purposes.

Aluminum extrusion involves forcing a heated aluminum billet through a custom die to create profiles with a defined cross-sectional shape. This process allows for the production of strong, lightweight, and precisely formed components used across various industries.

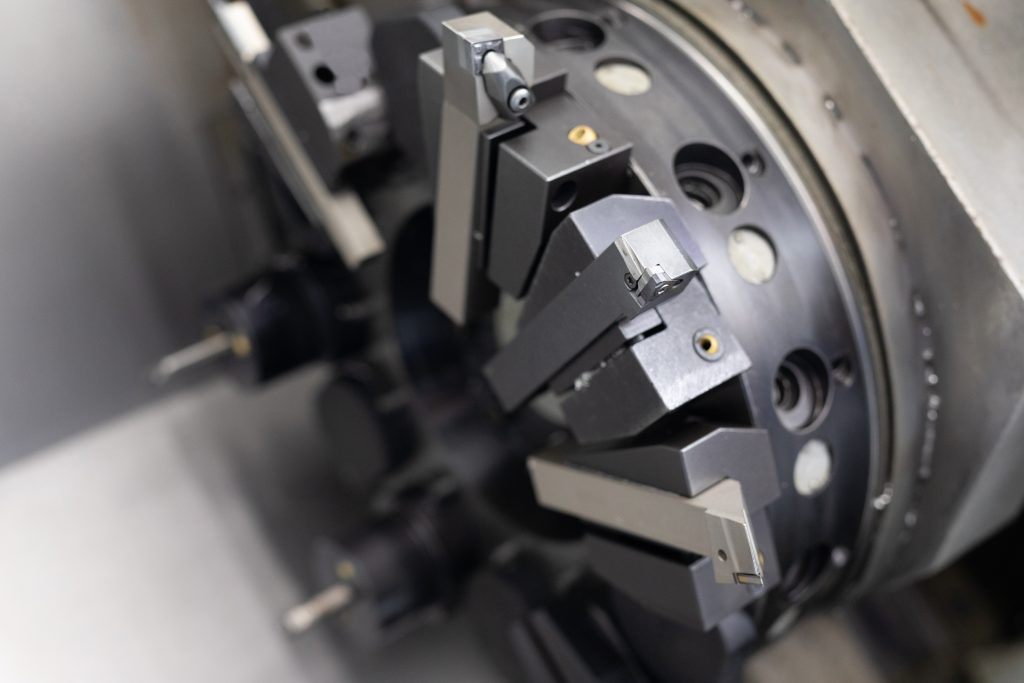

The process begins with die machining—whether solid, hollow, or semi-hollow—and billet preheating to temperatures typically between 400–500°C. The aluminum is then extruded using direct or indirect methods, under hot or cold conditions, depending on the alloy and application requirements.

After extrusion, the profiles are cooled, stretched, and cut to the desired length. Additional processes such as aging (to enhance strength and hardness), surface finishing (for improved appearance and performance), or assembly may follow.

Every custom aluminum extrusion undergoes rigorous inspection and secure packaging before shipment to ensure the highest quality and precision.

The tolerance for custom aluminum extrusions depends on the profile complexity, wall thickness, and extrusion press capability. In general, standard dimensional tolerances range from ±0.1 mm to ±0.5 mm. For precision applications, tighter tolerances can be achieved through secondary machining or CNC finishing. Factors such as die design, alloy type, and extrusion speed also influence the achievable precision.

Yes. While aluminum extrusions are commonly used for modular frames and gantries due to their strength, light weight, and easy assembly, there are other options available. Steel tubing, composite structures, and carbon-fiber-reinforced materials can be used where higher load-bearing capacity or rigidity is required. However, aluminum extrusions remain the most versatile and cost-effective non-welding solution because they allow assembly using T-slot connectors, fasteners, or corner brackets without the need for welding.

The ideal wall thickness for an extrusion profile depends on several design and production factors, including:

Application requirements (load, strength, and stiffness)

Profile design complexity and internal cavities

Alloy selection and temper

Extrusion press capability and die design

Cost and weight optimization goals

Balancing these factors ensures that the extrusion maintains structural integrity while minimizing material use and production cost.

While the exact thickness varies by design, most custom aluminum extrusions typically have wall thicknesses between 1.0 mm and 5.0 mm.

Thin walls (1–2 mm) are ideal for lightweight structures or decorative components.

Medium walls (2–4 mm) are used for general-purpose profiles like frames, channels, and supports.

Thicker walls (4 mm and above) are recommended for heavy-duty or load-bearing applications.

Choosing the right thickness depends on strength requirements, cost constraints, and intended use.

Yes, prototyping is an essential step in aluminum extrusion development. Before full-scale production, prototypes are created to verify fit, form, and function. This helps identify design improvements, optimize die geometry, and test mechanical properties. Low-volume or sample extrusions can be produced quickly to help reduce risk and ensure design accuracy before committing to mass production.