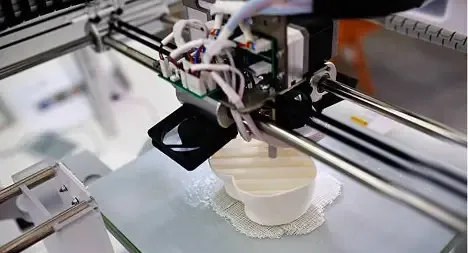

3D printing has been around for over three decades and is responsible for increased innovation in several manufacturing and prototyping industries. The reason for its potentiated adoption is not far-fetched, as such industries that use 3D printing enjoy reduced material wastage, increased increasing production efficiency, enhanced quality, and high accuracy, amongst other benefits.

What industries use 3D printing in their day-to-day activities, and why are other industries now realizing the importance of the technology? This article discusses industries using 3D printing and the different ways they make use of the technology.

Overview of the Use of 3D Printing Technology for Various Industries

3D printing technologies have widespread applications in different industries, especially recently. With the technologies, manufacturers and product designers in industries such as automotive, energy, aerospace, healthcare, and consumer products can prototype or manufacture different products using materials that range from plastics to metals. This section gives a detailed overview of the application of 3D printing technologies in some of the industries mentioned above.

Automotive Industry

The automotive industry is one of the industries that use 3D printing technologies in prototyping, customization, and tooling. Automotive companies using 3D printing, such as Ford and Volkswagen, currently champion the technologies relying on its design freedom, accessibility, enhanced creativity, and cost reduction. Below are the different ways by which the automotive industry makes use of 3D printing technologies.

1. Prototyping and design iteration

For several reasons, many automotive part manufacturers and designers encourage the adoption of 3D printing in automotive part prototyping. Firstly, unlike traditional prototyping methods, 3D prototyping is less time-consuming and more cost-efficient. Secondly, incorporating 3D printing into the design process can help quickly convert created digital models into prototypes.

3D printing makes it easy for designers to make 3D digital models and evaluate the printed 3D parts for flaws or needs for improvement. As a result, the automotive industry enjoys quicker design optimization to ensure that the manufactured parts through the prototype meet desired specifications and requirements.

2. Customization of parts and components

Another reason for the wide adoption of 3D printing in the automotive industry is its ease of customizing parts and components. The automotive industry is one of the few industries needing part customization to satisfy the growing customer appeal and improve functional performance.

After printing an automotive part, designers and manufacturers can modify the 3D models used for printing if there is a need for improvement in the printed parts. This process is crucial in producing automotive parts and components such as dashboards, console panels, door handles, grilles, and side mirrors. Furthermore, with customization, automotive parts can be tailored to customer or functional requirements.

3. Tooling and manufacturing aids

3D printing technologies can make tooling and manufacturing aids for specific automotive part production processes. With such technologies, manufacturers can make customized tools for a process and enjoy benefits such as cost reduction, as seen in 3D printing for making customized tools for their assembly line jigs. Other companies such as BMW and General Motors use 3D printing to create complex parts tools that help improve precision and streamline workflows.

4. Production of low-volume or specialty vehicles

Automotive part manufacturers now rely on 3D printing for making low-volume or specialty vehicles due to the faster prototyping and manufacturing process and the increased flexibility in design. Manufacturers such as Bugatti have used 3D printing in making limited-edition vehicles. The process’s accelerated production without losing quality has made it a crucial part of the fast cars niche. Furthermore, manufacturers can easily assess the vehicle and its parts before production. Also, third-party automotive part manufacturers now rely on the process of making parts.