In today’s fast-paced global market, mold design must adapt to current industrial needs and realities. With products having shorter lifespans, mold makers need innovative solutions to stay ahead. That’s where injection molding side action comes in. It is the game changer for handling complex geometries and tricky undercuts.

Designers and engineers must understand when and how to use the side actions to unlock its full potential. This article will explore side action, how it works, and the various types for your applications. We’ll break down the complexities and provide actionable tips to boost your precision molding capabilities. Our goal is to equip mold makers, designers, and manufacturers with the know-how to make informed decisions and stay competitive. Let’s get started!

What Is Injection Molding Side Action?

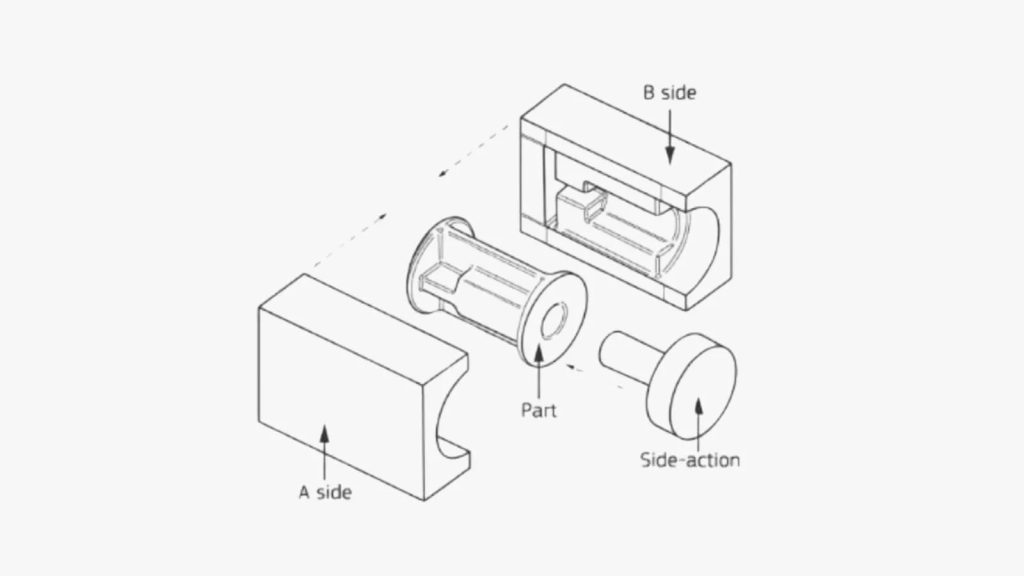

Side actions are specialized inserts that enable the creation of complex undercut geometries. These features are perpendicular to main parting line, making them impossible to produce with a standard straight-pull mold. With the incorporation of side actions into the mold design, the material can flow around them to form the undercut feature.

Side actions expand design possibilities by enabling complex part geometries. Their design allows them to address the undercut geometry, which poses a challenge in traditional straight-pull injection molding. In this process, the mold’s straight pull action is insufficient to release parts with undercuts. Injection molding side action overcomes this limitation by employing a cam-driven mechanism that withdraws the mold surfaces, allowing safe part ejection.

However, the use of side actions requires careful consideration. After molding the part, the side actions must be manually or automatically removed to facilitate part ejection. It’s crucial to assess whether they are necessary or if alternative design approaches, such as slot features, can achieve the desired outcome.

How Side Action Works?

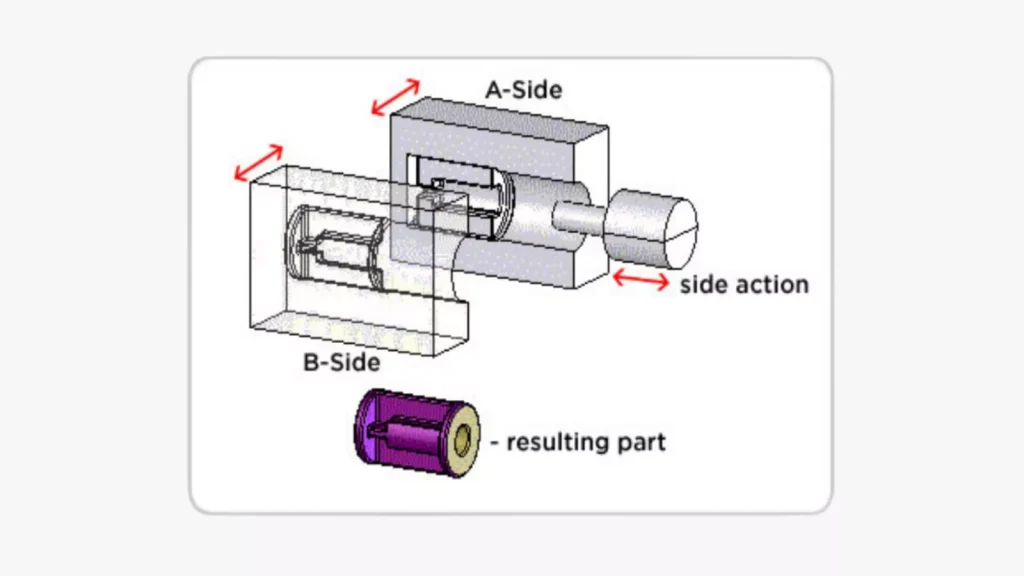

Side actions enable the creation of complex geometries with undercuts that cannot be achieved with a standard two-part mold. These undercuts are characterized by inward-facing angles or projections. As a result, they can make part removal challenging without causing damage.

To address this, manufacturers use lateral movements, where sideways slide, or cam action engage with the mold cavity during closure. This facilitates the creation of undercut areas on the part. Precise guidance is ensured through angle pins, which interlock with side actions and accurately position them to form undercuts. During mold closure, these pins drive the side actions into their designated positions.

Controlled retraction of side actions after molding enables smooth part ejection without interference. Hydraulic or mechanical actuators manage this process, ensuring seamless operations. Retracting side actions before part ejection prevents damage to molded elements with undercuts. Doing this will result in the efficient production of high-quality parts with intricate details.

Types of Side Actions

When there is a need for side actions in the injection molding process, selecting the right type is vital to minimize tooling costs. Your manufacturer can recommend the most appropriate one for your injection molded part, as each type has unique cost considerations. Here are the different side action types you can consider.

Cams

Cams are clever mechanisms that enable mold opening by withdrawing undercut mold surfaces from the part. A common cam design uses an angled pin to control the action’s movement, mirroring the mold’s opening and closing speed. This allows for increased geometric complexity in part design without requiring external adjustments or operator interventions.

They enable the creation of parts with intricate details that standard molding techniques cannot achieve, and provide increased accuracy and precision in part design. They also reduce the need for secondary operations like drilling or machining and are compatible with other side actions like lifters or sliders.

Nevertheless, the cam pin requires ongoing monitoring throughout the production cycle. Due to steel’s compressible nature, excessive load can cause pin deformation, affecting part quality. Regular cam pin maintenance and inspection are crucial to ensure consistent performance and part accuracy.

Lifters

Lifters are necessary when designing parts with internal undercuts or features that need to be released without a draft. These include internal threads or bosses that require a specific orientation. Their mechanisms eliminate the need for an angled pin and reduce the risk of pin deformation.

However, internal features like draft, bosses, and ribs may require modification to accommodate lifter motion. Moreover, an injection mold lifter design can be complex, requiring careful planning and testing. Furthermore, ejector plate design and timing will help ensure proper lifter activation and retraction.