Rubber molding is a versatile manufacturing process that can produce a wide range of products, from simple seals and gaskets to complex automotive parts. It is a cost-effective method that offers high precision and accuracy, making it a popular choice for many industries.

There are three main types of rubber molding: injection, compression, and transfer molding. Each method has its benefits and ideal applications. Therefore, understanding them will help you choose the right one for your project.

In the following sections, we will explore the different types of rubber molding in more detail. You’ll learn the different samples of injection molded rubber parts and their applications. We’ll also give you tips on choosing the most suitable technique for your needs.

What’s Rubber Molding?

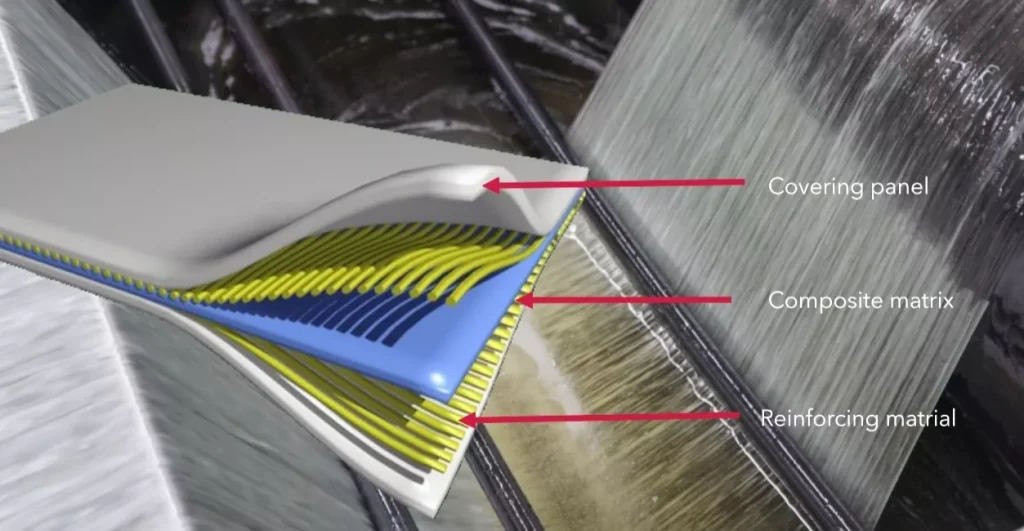

Rubber molding is a key manufacturing process that turns uncured rubber into durable, versatile parts tailored to diverse applications. This technique is integral to producing components with precision, capable of forming complex shapes and designs with outstanding durability. Its efficiency in mass production minimizes waste and ensures consistent quality, making it a cost-effective option for industries. The inherent resistance of rubber to harsh conditions, including extreme temperatures and corrosion, further elevates its value in demanding applications.

Moreover, the adaptability of rubber molding allows for extensive customization in rubber compounds, meeting specific performance requirements. This aspect is crucial in sectors where precision and material resilience are paramount, such as automotive and healthcare. As a result, rubber molding stands out as an indispensable process in the production landscape, providing robust, reliable, and tailored solutions that significantly enhance product performance and longevity.

How to Create Rubber Components

Suppose you are looking to produce a rubber product in large quantities. In that case, rubber molding is an efficient and cost-effective way to do it. Here are the basic steps involved:

Design the Mold

The first step is designing the mold. The mold will determine the shape and size of the end product. It is typically made of metal and can be designed to produce a single part or multiple parts at once. The design of the mold will depend on the product’s intended use, and it may include features such as ridges, holes, or other shapes.

When designing it, there are several considerations that you need to take into account.

- Material Selection: Choose a material suitable for the type of rubber you will be molding. The material should be able to withstand the high temperatures and pressures that are involved in the molding process.

- Part and Mold Design: The part’s design influences both mold construction and the molding process. Ensure compatibility with the selected rubber and molding technique. The mold should be designed to yield the desired part dimensions and shape.

- Venting: Venting is the process of allowing air to escape from the mold during the molding process. If air does not escape, it can cause defects in the product. Make sure your mold is adequately vented to prevent these defects from occurring.

- Cooling: Inappropriately cooled parts can end up with defects. So, you must consider cooling when creating the mold.