Top 13 Xometry Alternatives and Competitors for 2025

Are you looking for online manufacturing services for your prototyping or full-scale production? Xometry has been popular due to its resources on websites and offerings. Although its cloud-based quoting system can quickly analyze complex designs, several other Xometry competitors provide accurate information and guides for manufacturers globally. Furthermore, they can be suitable alternatives for outsourcing various on-demand parts and products.

What Is Plastic Extrusion: A Definitive Process Guide

Plastics are everywhere because of their versatility, longevity, and simpler manufacturing requirements. Plastic extrusion, along with injection molding, is one of the most common processes for high-volume production. Generally, extrusion is common for continuous profiles that use pipes, tubes, door profiles, and other bulky items.

Understanding the Differences Between Injection Molding and Extrusion

Part production requires careful consideration and planning regarding both the material and process selection. Injection molding vs extrusion is a popular debate because both processes can create repeatable plastic parts at a competitive speed. However, they have some differences as well.

Differences Between Waterjet Cutting vs Plasma Cutting

Waterjet cutting and plasma cutting aid in cutting and fabricating metal and other materials, but they differ considerably. These differences range from materials cut to the speed of cutting and even finishing

Abrasive vs Pure Waterjet Cutting: Which Is Better

When it comes to cutting materials, abrasive waterjet cutting vs pure waterjet cutting are two popular methods. Both techniques use high-pressure water to cut materials, but differ in how they do it. Abrasive waterjet cutting uses abrasive material to cut, while pure waterjet cutting only uses pressurized water.

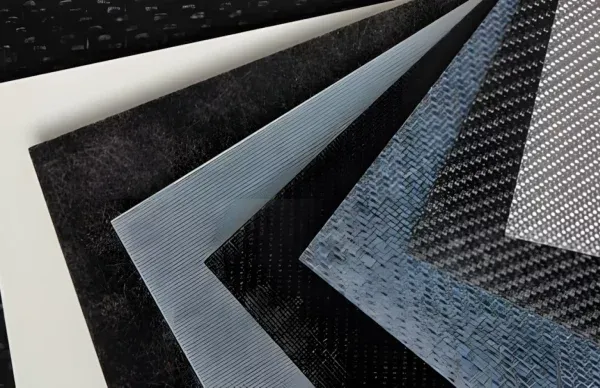

What’s Composite Material? Types and Uses

Rubber molding is a versatile manufacturing process that can produce a wide range of products, from simple seals and gaskets to complex automotive parts. It is a cost-effective method that offers high precision and accuracy, making it a popular choice for many industries.

What Is Rubber Molding? 3 Ways to Make Rubber Molded Parts

Composite materials combine two different materials having varying chemical and physical properties. This combination leads to the creation of a material designed to perform a specific task such as becoming electricity-resistant, lighter, stronger, or improving stiffness.

Vapor Polishing for Smooth, Glossy Surfaces: A Complete Guide

Have you ever wondered how to achieve a flawless, gloss […]

What’s Annealing: A Guide to Strengthening Materials

When it comes to improving material functionality while providing some level of assurance, then one process that comes into play for all industries is annealing. Whether it is metallic materials, alloys, or even glass, annealing has the capability of changing material properties. Yes! Annealing makes the material easier, tougher, and more suitable for further processing.

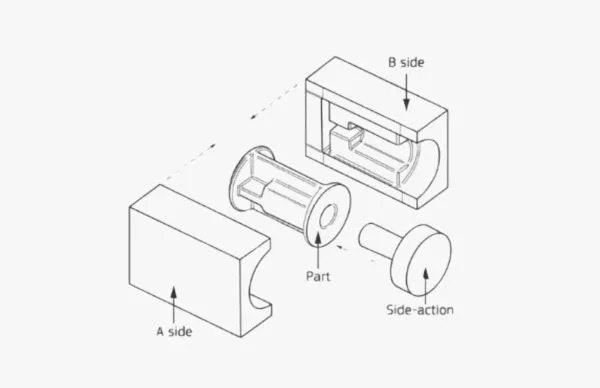

Using Injection Molding Side Action for Design Optimization

In today’s fast-paced global market, mold design must a […]