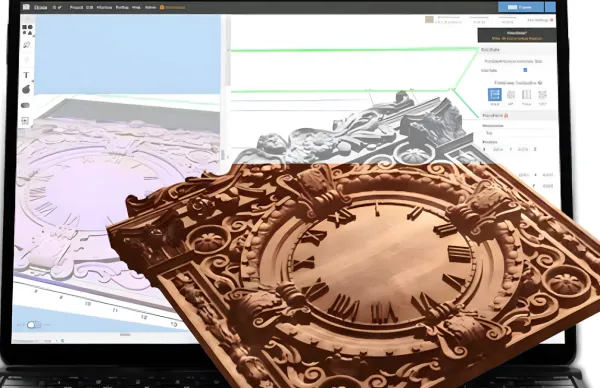

Best CNC Software for CNC Machines from Beginner to Expert Level

The right CNC software will be of use regardless of whe […]

What’s Shell Molding: Process, Materials, and Applications

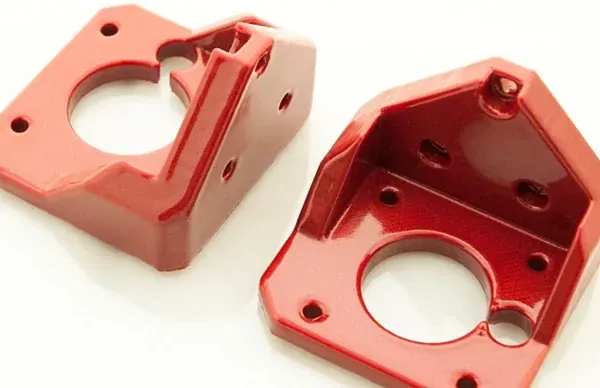

Among several metal parts manufacturing processes, metal casting is known for its capability of complex shapes, material versatility, and high-volume production. But what is casting exactly? It is the process of converting raw metal and alloys into desired functional parts by pouring their molten form into a pre-designed die cavity, followed by solidification. Meanwhile, the die cavity is the mirror of the intended part geometry.

What’s Casting? Types, Pros, Cons, and Applications

Among several metal parts manufacturing processes, metal casting is known for its capability of complex shapes, material versatility, and high-volume production. But what is casting exactly? It is the process of converting raw metal and alloys into desired functional parts by pouring their molten form into a pre-designed die cavity, followed by solidification. Meanwhile, the die cavity is the mirror of the intended part geometry.

Laser Cutting vs Plasma Cutting: A Detailed Guide

Although both plasma and laser involve heat to cut (or […]

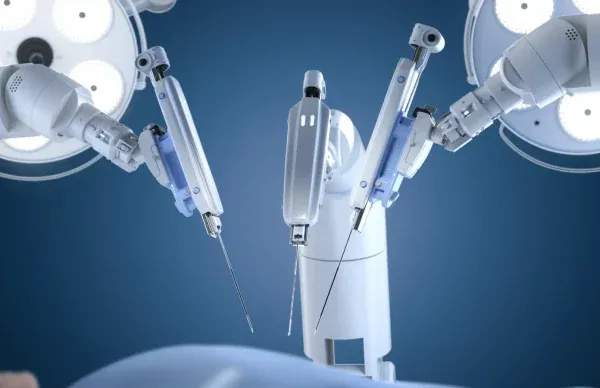

Vacuum Casting for Medical Devices: Benefits and Applications

In the medical field, when developing new products, precision, material compatibility and time are crucial. There, you need a method that supports medical-grade materials and produces quick results. One method that fulfills this criterion is vacuum casting.

Vacuum Casting Material Selection: Find the Best-fit Resin

Vacuum casting, also known as urethane casting or polyurethane casting is a versatile manufacturing process primarily used for highly accurate and detailed prototypes or parts in small batches. It involves pouring liquid material into a silicone mold under vacuum. Then, the material fills the mold without air bubbles or defects. Moreover, you have many vacuum casting materials options to choose from. It facilitates the best-fit material resin according to the desired properties and functionalities in the final part.

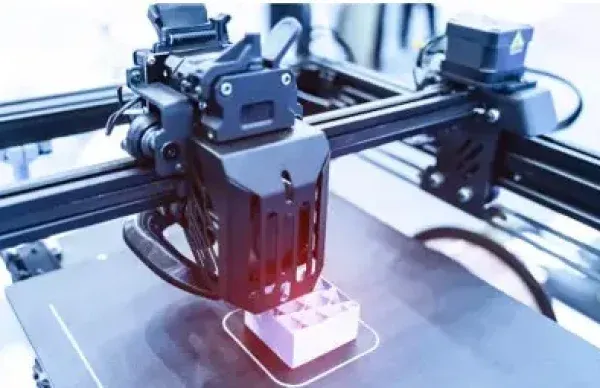

Top 6 Industries Use 3D Printing: A Wide Range of Industrial Applications

3D printing has been around for over three decades and is responsible for increased innovation in several manufacturing and prototyping industries. The reason for its potentiated adoption is not far-fetched, as such industries that use 3D printing enjoy reduced material wastage, increased increasing production efficiency, enhanced quality, and high accuracy, amongst other benefits.

What industries use 3D printing in their day-to-day activities, and why are other industries now realizing the importance of the technology? This article discusses industries using 3D printing and the different ways they make use of the technology.

ABS Acetone Smoothing: Methods, Materials, and Practical Tips

ABS is a popular and cost-effective 3D printing filamen […]

Medical Injection Molding: Process, Benefits, and Applications in Healthcare

Are you facing difficulties in creating medical components that need a specific level of safety, precision, and accuracy? There’s some good news that with medical injection molding, you no longer need to worry about high accuracy, consistent quality, and cost-effectiveness.

Flow Mark in Injection Molding: Causes and Prevention

Injection molding is a popular manufacturing method for plastic parts. This technology is efficient for high-volume production, maintaining repeatability and cost-effectiveness. However, any deviation in tooling, process variables, and raw material quality causes various defects in molded parts. A flow mark in injection molding is one major defect that influences the finish and aesthetic appeal.