High-quality metal and plastic parts with tight tolerances, fast lead times, and certified manufacturing you can rely on.

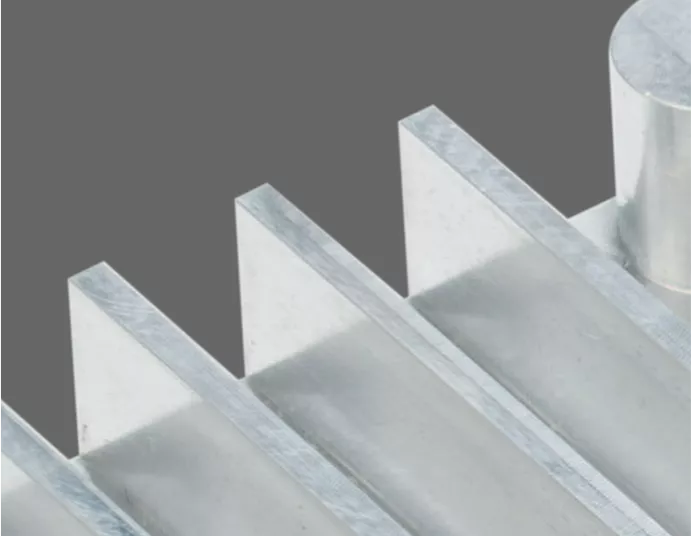

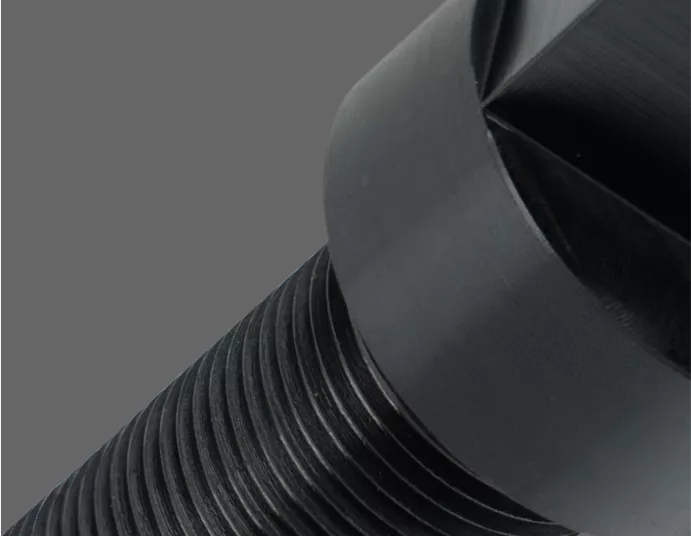

Bludeek is your trusted partner for high-quality CNC prototypes and production parts — from simple components to complex assemblies. Equipped with advanced CNC milling, turning, drilling, EDM, and precision grinding capabilities, we deliver exceptional accuracy and consistency. Our ISO 9001-certified processes and skilled engineering team ensure every part meets the highest quality standards.

Bludeek is your trusted partner for high-quality CNC prototypes and production parts — from simple components to complex assemblies. Equipped with advanced CNC milling, turning, drilling, EDM, and precision grinding capabilities, we deliver exceptional accuracy and consistency. Our ISO 9001-certified processes and skilled engineering team ensure every part meets the highest quality standards.

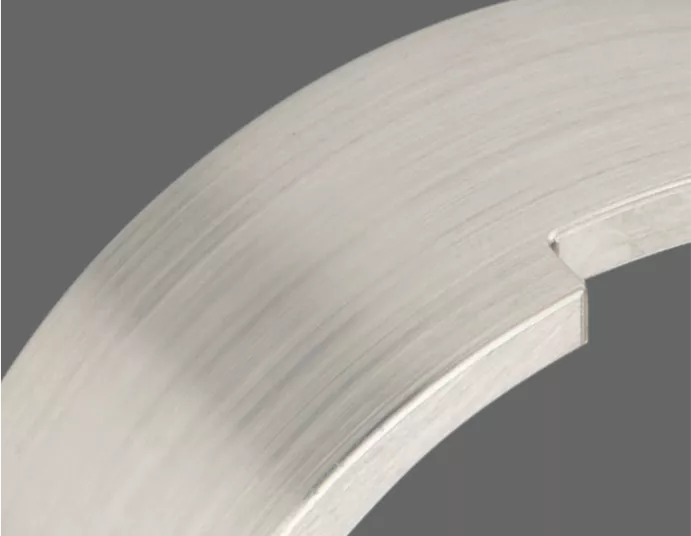

With advanced CNC lathes, turning centers, and mill-turn equipment, Bludeek produces high-precision cylindrical, square, and hexagonal components with exceptional accuracy. From rapid prototypes to full production runs, our turning services ensure fast turnaround and consistent quality — delivered within just a few days

Looking for the perfect finish? Bludeek offers over 20 surface finishing options to enhance both the performance and appearance of your machined parts.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

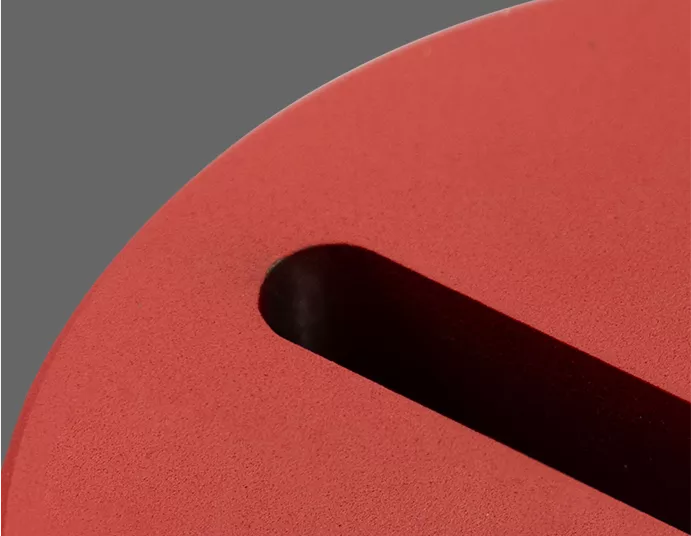

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

At Bludeek, we understand that superior quality is the foundation of every successful project. Our team of skilled engineers and technicians is dedicated to delivering precision, reliability, and consistency at every stage of CNC machining — from prototype development to full-scale production.

We implement a comprehensive quality control and assurance system across all machining processes, ensuring that every component — whether simple or complex, small batch or mass production — meets exact specifications. Each part undergoes strict inspection using advanced equipment, including CMMs, 2D measuring instruments, XRF analyzers, gauges, micrometers, and calipers.

Our quality engineers meticulously verify dimensional accuracy, material integrity, and functional performance, inspecting both prototypes and finished parts. Any deviations are promptly corrected to maintain Bludeek’s uncompromising quality standards.

With decades of manufacturing experience and ISO 9001:2015 certification, Bludeek consistently meets the demanding requirements of global industries such as automotive, electronics, and precision engineering.

20+ types of inspection equipment

30+ experienced quality engineers

Certified in ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

At Bludeek, quality comes first. Our ISO-certified CNC machining processes ensure every component meets exact specifications — built for accuracy, durability, and superior performance. Each part undergoes strict multi-stage inspection to guarantee flawless results from start to finish.

We understand that time is critical in manufacturing. With advanced production equipment and an efficient workflow, Bludeek delivers parts quickly without compromising quality — helping you stay on schedule and ahead of your competitors.

Our experienced engineering and technical support team works closely with you to optimize designs, improve manufacturability, and reduce production costs. Whether it’s a prototype or a large-scale order, Bludeek ensures your project runs smoothly from concept to completion.

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machines to precisely remove material from a workpiece to create custom parts. It’s ideal for producing both prototypes and high-volume production parts with consistent accuracy.

We work with a wide range of materials, including aluminum, stainless steel, brass, copper, titanium, mild steel, and various plastics such as ABS, POM, nylon, and acrylic.

Bludeek provides CNC milling, CNC turning, EDM, surface grinding, and assembly. We also offer molding and fabrication services for complete project support.

Our standard tolerance is ±0.01 mm, and tighter tolerances are available upon request, depending on part geometry and material type.

Lead times depend on part complexity and quantity, but prototype parts can often be completed within 3–7 days, and batch production within 2–3 weeks.

Yes. We support one-off prototypes, small batches, and mass production runs — ensuring the same level of precision and quality for every order.

Absolutely. We offer anodizing, powder coating, polishing, sandblasting, plating, and painting, as well as custom surface treatments upon request.

We perform multi-stage inspections — including incoming material checks, in-process inspections, and final quality verification — using advanced equipment such as CMMs, micrometers, and XRF analyzers.

Yes. Our experienced engineering team assists clients in design optimization, material selection, and manufacturability analysis to ensure the best results at the lowest cost.

Simply send us your 3D/2D drawings (STEP, IGES, or PDF) along with your material, quantity, and surface finish requirements. Our team will review your files and provide a detailed quotation within 24 hours.