Advanced milling technology delivering accuracy, speed, and reliability worldwide.

From small prototypes to large-scale production, we deliver consistent, high-quality machined parts.

Our advanced CNC technology ensures smooth finishes, tight tolerances, and reliable performance.

Whatever your industry, we turn your designs into precision-crafted components that last.

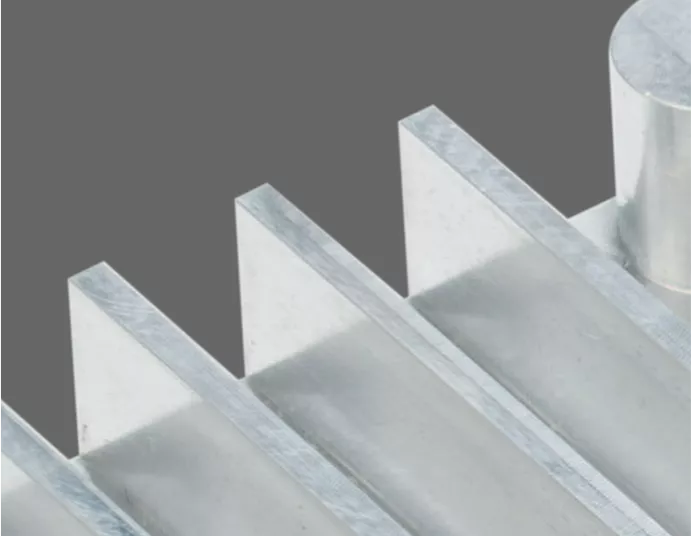

With 3-axis CNC milling, precision meets affordability. It’s your go-to for simple parts that still demand accuracy

Our 4-axis CNC milling provides enhanced precision and efficiency for complex parts.

By adding a rotating axis, we can machine multiple surfaces in a single setup — reducing time, improving accuracy, and ensuring consistent quality.

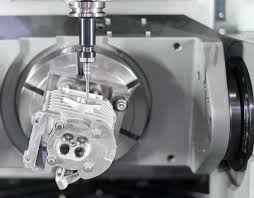

Our 5-axis CNC milling delivers unmatched precision for highly complex parts.

With simultaneous movement along five axes, we can machine intricate geometries and multi-surfaced components in a single setup.

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

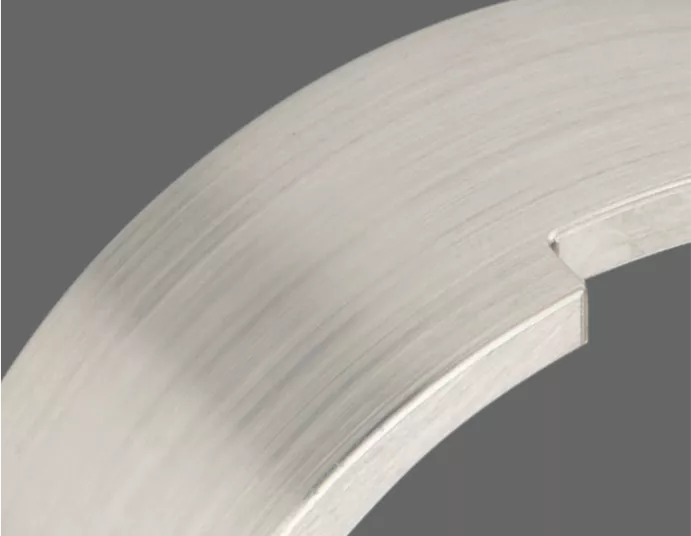

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

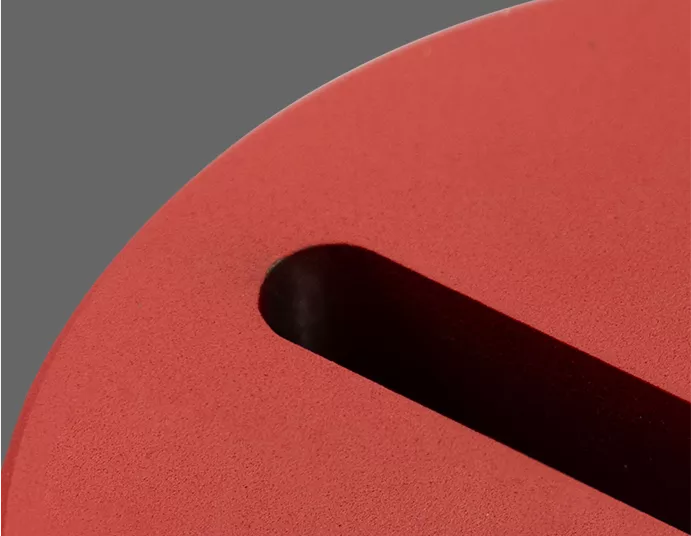

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

With our online CNC milling services, you’re not just accessing advanced machinery. You gain: precision, reliability, and the expertise of seasoned professionals who ensure your custom parts are produced flawlessly and delivered on time.

Every part is crafted with precision using state-of-the-art CNC machines.

We maintain tight tolerances and smooth finishes, ensuring parts fit perfectly and perform flawlessly.

Accelerate your production without compromising accuracy.

Our streamlined processes and advanced equipment deliver fast, reliable results — helping you meet critical project deadlines.

Our engineering team is with you every step of the way.

From design optimization to final production, we provide guidance to maximize efficiency and quality.

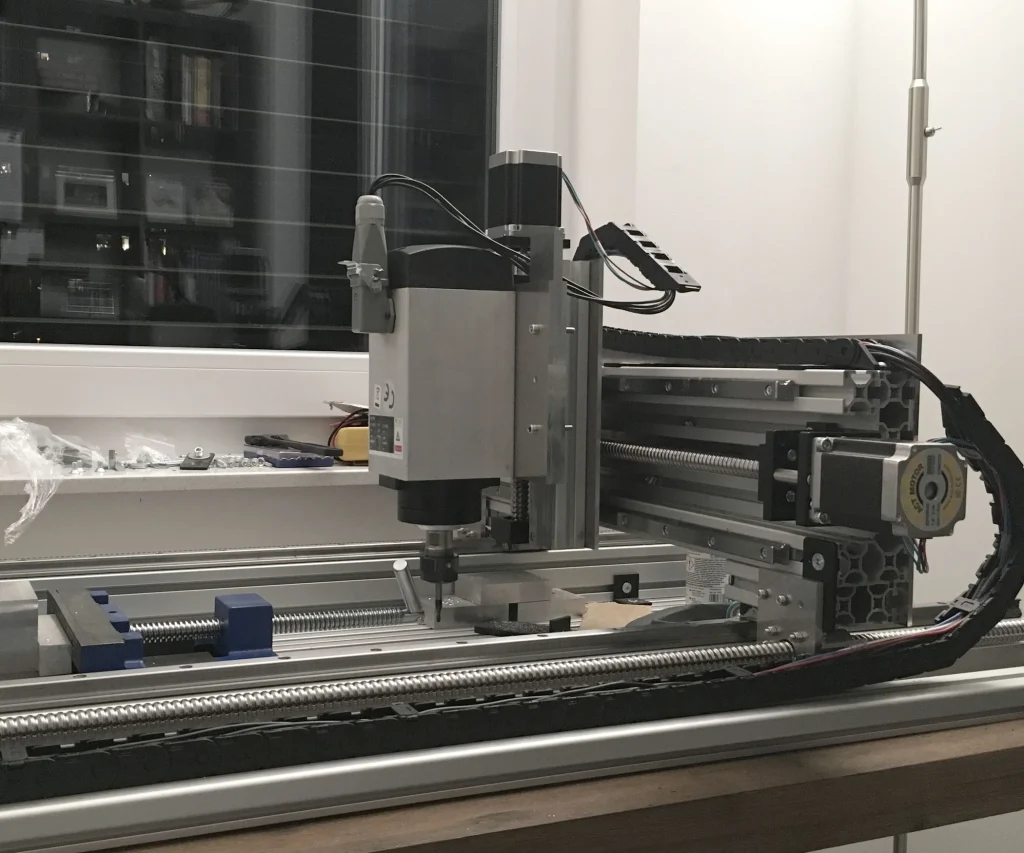

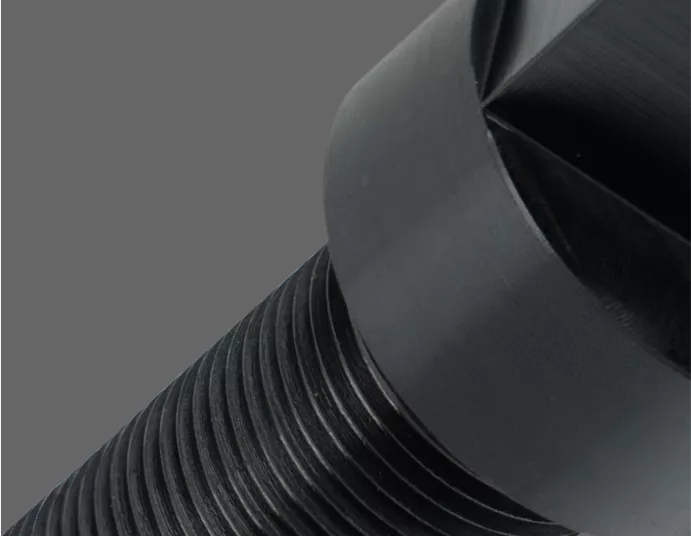

CNC milling is a precise manufacturing method that removes material from a workpiece using high-speed rotating cutting tools. The process starts with a digital design, typically created in CAD software, which is then converted into a CNC program to guide the milling machine’s movements.

The workpiece is securely fixed to the machine table, and the cutting tool spins at high speeds to follow the programmed path, making accurate cuts to form the desired shape. CNC milling can produce complex features such as holes, slots, and contours with exceptional precision.

Different milling configurations offer varying capabilities:

3-axis milling: Moves the tool along the X, Y, and Z axes.

4-axis milling: Adds rotation around one axis for more complex parts.

5-axis milling: Allows rotation around two axes, enabling intricate and multi-faceted designs.

This versatility makes CNC milling a critical process across industries, from aerospace and automotive to medical devices and electronics.

We offer 3-axis, 4-axis, and 5-axis CNC milling machines to handle everything from simple cuts to complex, multi-axis parts.

What’s the difference between CNC milling and CNC turning?

5-axis CNC machines move the tool along X, Y, Z axes and rotate around two additional axes, enabling complex shapes in a single setup.

CNC mills can machine metals, plastics, composites, and other materials depending on tooling and machine configuration.

Vertical mills have a vertically oriented spindle for flat or shallow parts, while horizontal mills have a horizontally oriented spindle for deeper cuts and complex geometries.