Bludeek offers end-to-end die casting solutions — from tooling and mold design to finishing and quality control. Our experienced team ensures your parts meet exact specifications, with tight tolerances, excellent surface finish, and consistent performance. Perfect for automotive, industrial, and consumer applications.

Experience precision 3D printing tailored to your exact requirements. From rapid prototyping to full-scale production, we deliver high-quality custom parts with exceptional accuracy and speed. Using advanced technologies such as SLA, SLS, HP MJF, and SLM, we produce detailed components with tolerances as fine as ±0.2 mm. Partner with our 3D printing specialists for consistent, high-resolution results that bring your designs to life.

To meet diverse project requirements, Bludeek offers several die casting processes tailored to different materials and design complexities. We specialize in hot chamber and cold chamber die casting for high-precision parts. For components requiring tight tolerances and superior structural strength, we also provide advanced techniques such as semi-solid die casting, ensuring reliable performance and exceptional quality.

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

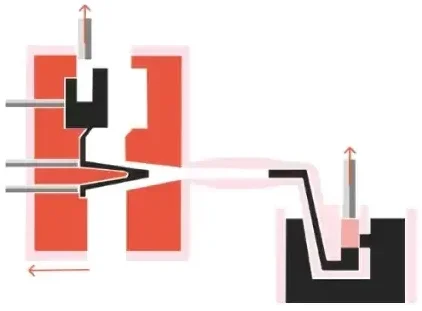

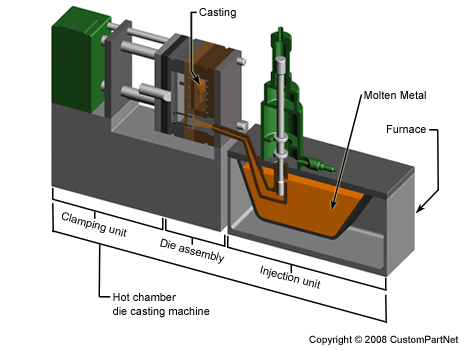

Die casting is a high-precision metal casting technique in which molten metal is injected into a mold cavity under high pressure. It is widely used for producing complex metal parts with tight dimensional accuracy, smooth surfaces, and excellent repeatability, particularly in high-volume production.

The process utilizes hardened steel dies, often machined with CNC equipment, which can be single or multi-cavity depending on production requirements. Non-ferrous metals are melted in furnaces and then injected into the dies using specialized casting machines.

The choice of machine—hot chamber or cold chamber—depends on the metal being cast. For intricate components like transmission cases, engine mounts, and electronic housings, semi-solid die casting offers enhanced strength and superior surface finish.

When designing for die casting, consider wall thickness, draft angles, uniformity, and fillets to ensure proper metal flow and reduce defects. Also, plan for shrinkage, tolerances, and part ejection to achieve optimal quality and manufacturability.

Yes, die cast parts can be post-machined for features that require tight tolerances or precise finishes. While many parts have smooth surfaces straight from the mold, additional machining can enhance dimensional accuracy or prepare parts for assembly.