From prototype to high-volume production, Bludeek delivers expertly designed molds, advanced tooling, and consistent quality to bring your plastic parts to life—on time, on spec, and at competitive costs.

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

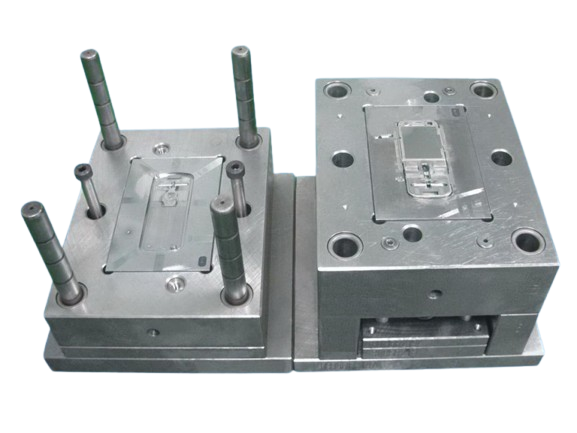

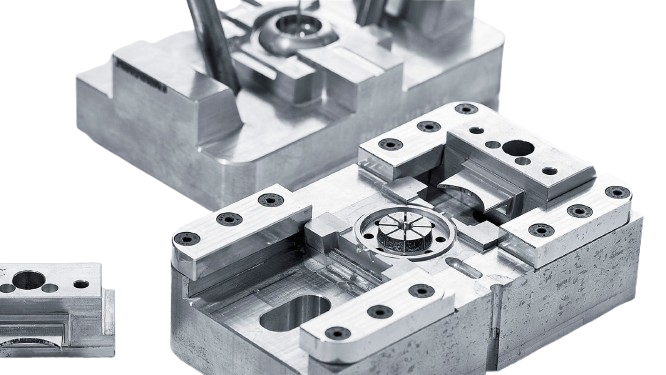

Bring your injection-molded parts to life with precision and innovation. At Bludeek, we design and manufacture custom injection molds that ensure exceptional quality and project success. Our team collaborates closely with you to understand every detail of your product, creating accurate mold designs that meet your exact specifications. Skilled engineers and technicians manage every stage of tooling — from concept to completion — with efficiency and expertise.

Our flexible approach allows us to deliver both prototype molds and full-scale production tools at competitive prices. With rapid lead times and advanced manufacturing capabilities, we help you accelerate production and bring products to market faster. Ready to elevate your plastic part production? We’re here to make it happen.

Get quick design validation and functional feedback with high-quality prototype tooling. We produce small batches of precision-molded plastic parts for testing and evaluation. Our team delivers prototype molds within days, helping you assess performance and market potential early. Using cost-effective aluminum tooling, we minimize financial risk and speed up your path to full-scale production.

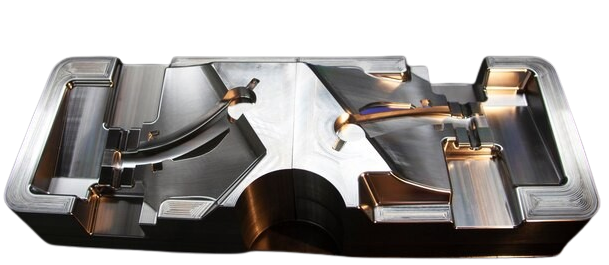

We manufacture durable, high-performance production molds built for large-scale plastic part manufacturing. Made from premium tool steel, our molds deliver strength, longevity, and consistency across hundreds of thousands of cycles. Every tool is customized to your specifications — with adaptable materials, design methods, and finishes to suit your production needs.

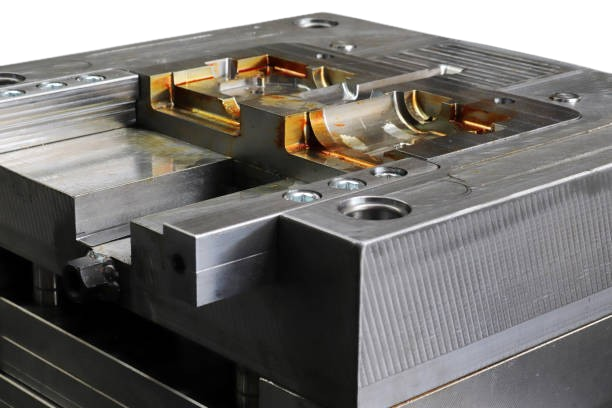

Bludeek is your trusted partner for high-quality CNC prototypes and production parts — from simple components to complex assemblies. Equipped with advanced CNC milling, turning, drilling, EDM, and precision grinding capabilities, we deliver exceptional accuracy and consistency. Our ISO 9001-certified processes and skilled engineering team ensure every part meets the highest quality standards.

Achieve efficient low-volume production with precision-engineered single cavity molds. This cost-effective tooling option provides excellent quality and greater control over the injection molding process for small batch manufacturing.

Produce multiple high-quality plastic parts in each cycle with precision multi-cavity molds. Designed for efficiency and consistency, this tooling solution maximizes productivity, reduces per-unit cost, and ensures optimal use of cycle time for large-scale manufacturing.

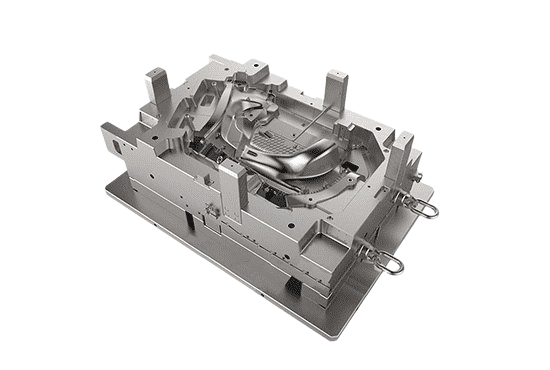

Boost your production efficiency with advanced stack mold tooling designed for high-output manufacturing. Our precision-built stack molds double productivity while minimizing part costs, featuring customizable cavity layouts on each parting surface — ideal for producing multi-component assemblies in a single cycle.

Experience a smarter way to produce complex parts with our 2K injection mold solutions. This process allows two different plastic materials—soft and hard—to be molded together in one seamless operation. The result is a durable, high-quality component that reduces assembly time, cuts costs, and enhances design flexibility for custom applications.

Before beginning any injection molding project—whether for low- or high-volume production—precision CNC-machined tooling is essential. The most commonly used materials for mold fabrication are high-grade tool steels, chosen for their strength and durability.

Common types include: P20, H13, S7, NAK80, S136, S136H, 718, 718H, and 738.

Injection molds are typically made from steel and stainless steel, materials known for their durability but higher manufacturing costs. Because of this, they are most suitable for large-scale production runs.

Common types include: 420, NAK80, S136, 316L, 316, 301, 303, and 304.

Aluminum molds are a cost-effective alternative to traditional steel and carbon steel molds. They provide faster cycle times and quick turnaround, making them ideal for prototyping and market testing.

Common types include: 6061, 5052, and 7075.

Injection molds are costly due to the use of high-quality materials like hardened steel or aluminum, complex manufacturing processes (CNC machining, EDM, polishing), and the need for high precision. Custom designs tailored to specific parts and extensive engineering efforts also contribute to higher costs.

Mold design depends on the part geometry, size, and complexity, the type of plastic material, required tolerances, and specialized features like ejection systems, gate locations, undercuts, and parting lines. All these factors determine mold performance, cycle time, and cost.

Different plastics behave differently under heat and pressure. Materials like polypropylene shrink more, while polycarbonate requires higher mold temperatures. Mold materials must resist wear and corrosion from the selected plastic, and the design must accommodate material-specific flow, cooling, and shrinkage.

High-precision molds ensure parts meet tight tolerances, especially in industries like automotive, aerospace, and medical. Achieving this requires advanced equipment, skilled technicians, and careful design of cooling channels, gating, and ejection systems to maintain consistency across production runs.