Produce accurate, high-quality laser-cut parts for both prototypes and production runs. Get a free quote with expert DFM feedback within 24 hours and enjoy rapid lead times of 3–5 days for quick project turnaround.

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

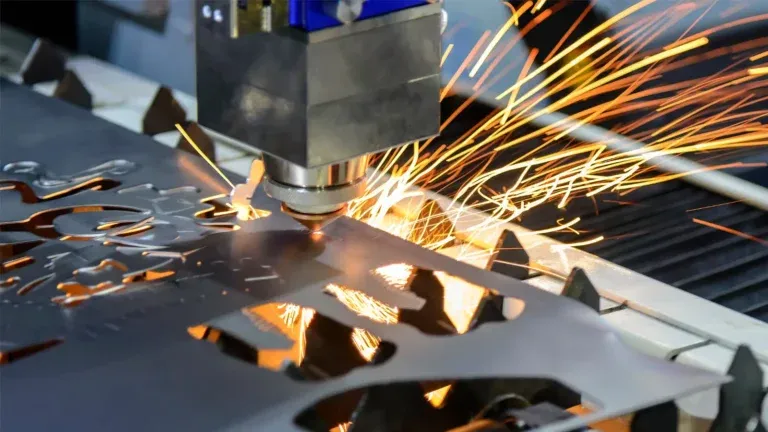

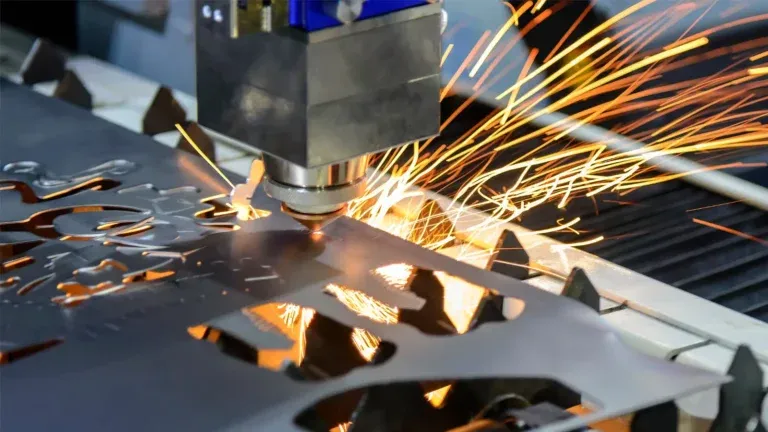

Laser cutting is a highly precise manufacturing process that uses a focused laser beam to cut or etch materials into custom shapes and intricate designs. This method delivers clean edges, high accuracy, and consistent results, making it ideal for prototypes, functional parts, and production components.

At Bludeek, our online laser cutting services support a wide range of materials, including metals, plastics, and wood, providing flexibility for any project. Whether you need a single prototype, low-volume runs, or high-volume production, our advanced laser cutters handle complex designs efficiently.

To simplify your workflow, we offer a real-time online quoting system that accepts multiple CAD file formats. Upload your design, get an instant quote, and move seamlessly from concept to production, saving time and cost. Our service combines speed, precision, and accessibility to meet all your manufacturing needs effectively

Fiber laser cutters at Bludeek deliver high-precision results with minimal setup time, making them ideal for cutting reflective metals. They are highly energy-efficient and provide fast cutting speeds, perfect for both custom projects and high-volume metal fabrication.

CO2 laser cutters excel at processing a wide variety of materials, including metals, plastics, and wood. With a fine, focused beam, CO2 technology ensures clean cuts, intricate details, and superior edge quality, enhancing the finish and accuracy of your parts.

Nd:YAG lasers are designed for high-power applications, capable of cutting thick and hard materials with extreme precision. At Bludeek, Nd:YAG cutters are used for complex industrial and custom designs where deep cuts and exceptional accuracy are required.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Discover the precision of the RapidDirect laser cutting shop, where modern technology meets skilled work. Our shop houses seven high-tech laser cutters, each with a capacity of 3000*1500, able to cut up to 30mm thick plates with a precision of ±0.01mm. This allows us to work with a wide variety of materials, from metals to plastics and woods, ensuring top-quality results for every project.

Take a closer look at our operations by watching our video tour. See how our laser cutting services bring precision and efficiency to each custom project, demonstrating our dedication to excellence.

Bludeek laser cutters achieve high precision with tolerances up to ±0.01 mm, ensuring clean, accurate edges and consistent results for all materials.

Our facility can laser cut sheets up to 30 mm thick, depending on the material type, from metals to plastics and wood.

Yes, we provide custom laser engraving and etching services for detailed designs, logos, or decorative patterns on a variety of materials.

Absolutely. After precise laser cutting, Bludeek can assist with secondary processes such as bending, forming, or welding to achieve the desired part geometry.

Lead times vary by project size and complexity: rapid prototypes can be ready in 3–5 days, while larger production runs may take 1–3 weeks, depending on volume.