Precision metal bending services for prototypes and production parts. Get a free quote with expert DFM feedback within 1 day, with fast lead times of just 3–5 days for rapid project turnaround.

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

Metal bending is a fabrication process that shapes metal sheets into precise angles or forms using mechanical force. This technique is essential for creating durable, functional components with accurate curves and bends, widely used across industries like automotive, electronics, and construction.

At Bludeek, our sheet metal bending services cater to both simple and complex designs. We utilize advanced electric and hydraulic press brakes to ensure precision, even on parts with tight tolerances. You can easily upload your 3D CAD files through our platform to receive an instant quote, streamlining your workflow from design to production.

Beyond bending, Bludeek offers post-processing options to deliver parts that are not only perfectly formed but also ready for immediate use, whether for prototypes or full-scale production.

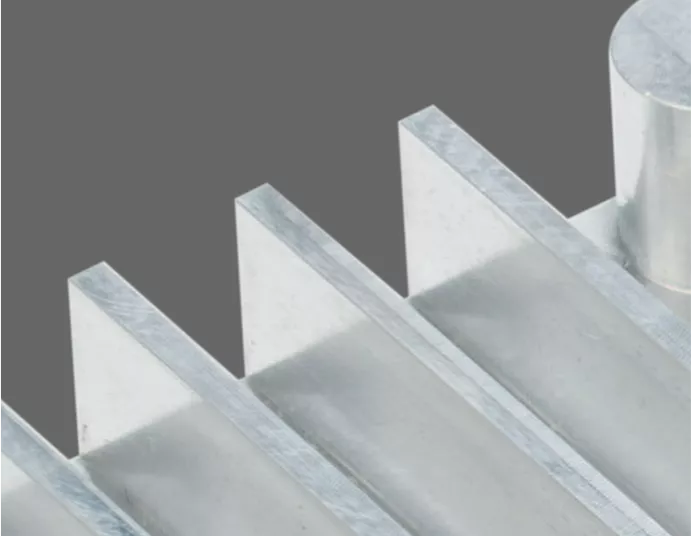

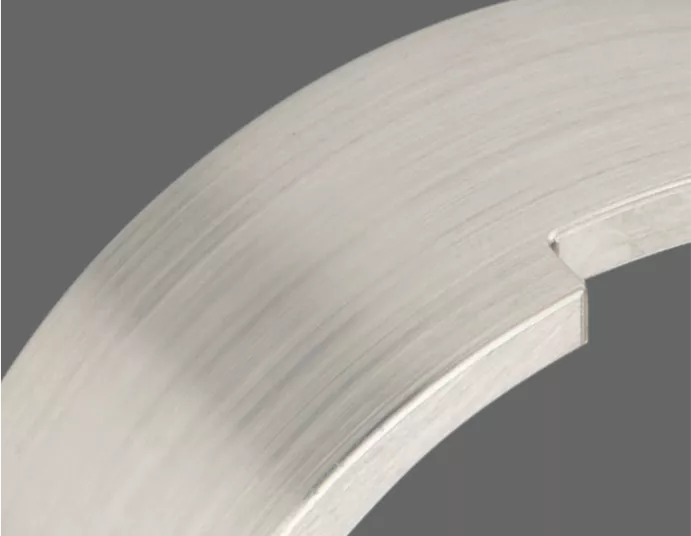

Metal bending is a key process in sheet metal fabrication, involving the controlled deformation of metal into specific shapes using mechanical force. This process enables the precise creation of V, U, or channel profiles, essential for both structural and aesthetic applications. Bending can be performed using manual methods or advanced CNC (Computer Numerical Control) machines, which provide high precision, repeatability, and efficiency.

In the bending process, a sheet metal piece is positioned between a punch and a die. The punch presses the metal into the die cavity, forming it to the desired angle and shape. Critical factors such as bend angle, bend radius, bending force, and material properties (like ductility and thickness) determine the quality and accuracy of the final part without significantly altering the metal’s thickness.

Metal bending is widely used across industries due to its ability to produce strong, functional, and precisely formed components efficiently. From small brackets to large structural or architectural elements, the process allows for highly accurate and repeatable results. Modern CNC bending technology further enhances design flexibility, reduces production time, and ensures consistent quality, even for large-volume manufacturing runs.

At Bludeek, our surface finishing services improve both the strength and visual appeal of bent metal components, ensuring they meet the stringent quality standards demanded across various industries.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

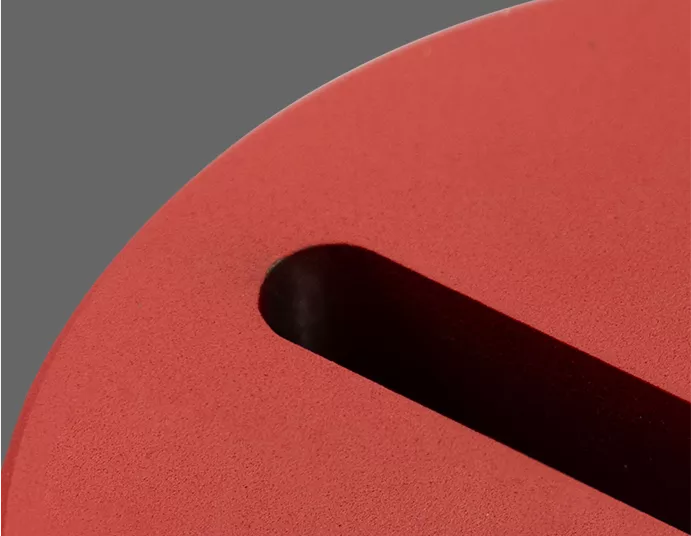

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

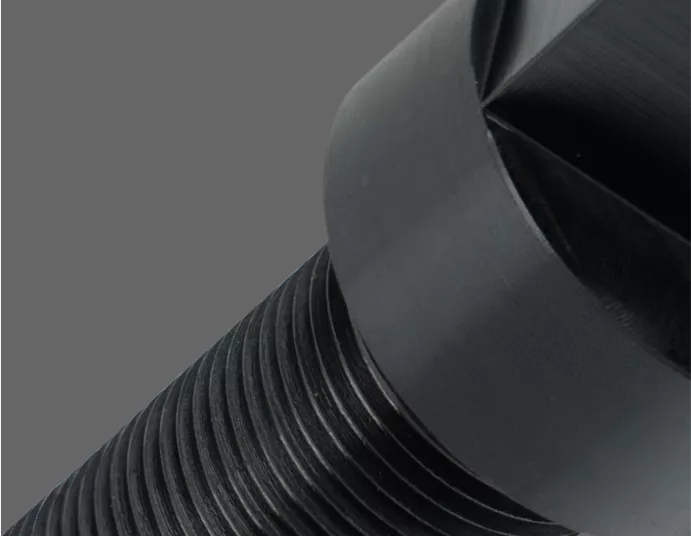

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Metal bending converts flat metal sheets into precisely shaped 3D components using controlled force and advanced machinery. Before bending, sheets are typically prepared through laser cutting or other precision methods to ensure accurate dimensions. At Bludeek, we use high-tonnage press brakes capable of applying up to 200 tons of force, accommodating materials up to 3200 mm in length. Each bend is executed with exact tooling, ranging from R3 to R50, achieving a tight tolerance of ±0.1 mm.

This precise metal bending process is ideal for a wide range of applications, including machinery parts, structural components, and custom furniture. Our expertise allows us to deliver customized solutions with consistent quality and exceptional accuracy, meeting the specific requirements of every project.

Experience the precision and efficiency of our operations by watching a video tour of our facility, showcasing how Bludeek combines advanced technology with skilled craftsmanship to produce high-quality bent metal parts.

Metal bending uses controlled force to transform flat sheets into precise 3D shapes, typically using press brakes or CNC machinery.

Lead times depend on complexity and volume, with rapid prototypes ready in 3–5 days and larger production runs in 1–3 weeks.

Bludeek achieves tight tolerances, typically around ±0.1 mm, ensuring precise and consistent results.

Minor die marks may appear, but careful tooling and finishing processes minimize visibility for a smooth, high-quality finish.

Yes, Bludeek can accommodate custom angles and bend radii to meet specific design requirements.

Materials with higher ductility, such as aluminum and mild steel, are generally easier to bend without cracking.

We use advanced CNC press brakes, inspection tools, and ISO-certified processes to maintain accuracy, consistency, and high-quality standards for every project.