Experience the power of advanced CNC technology designed to deliver absolute accuracy, smooth finishes, and consistent quality across every project. Our precision machining solutions are ideal for producing complex, tight-tolerance components for aerospace, medical, automotive, and electronic industries — ensuring every part performs flawlessly, every time.

Precision CNC machining combines cutting-edge technology with expert craftsmanship to produce highly accurate and complex parts across industries such as aerospace, automotive, medical, and electronics. Using advanced computer-controlled machinery, every component is manufactured to meet exact specifications for size, shape, and performance.

This process allows for the creation of intricate geometries and detailed features that traditional machining methods cannot achieve. With the ability to maintain tight tolerances and superior surface finishes, precision CNC machining ensures consistent quality and reliability across every production run.

At our facility, we utilize state-of-the-art CNC equipment to deliver precision-engineered parts like gears, brackets, enclosures, and structural components. Whether you need prototypes or large-scale production, our precision CNC services guarantee accuracy, repeatability, and durability for every project.

We are dedicated to providing comprehensive machining solutions that help our clients achieve performance excellence, reduce production time, and meet the highest industry standards.

RapidDirect’s wire EDM, part of our CNC services, efficiently crafts both simple and intricate shapes. Ideal for parts requiring high precision, this no-contact method produces minimal burrs and excels with metals like steel and titanium. Favored in aerospace, automotive, and electronics for their accuracy, we ensure tailored, precise solutions regardless of your needs.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (based on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Cutting Speed | Up to 300 mm2/min (specific to material and thickness) |

| Surface Finish | As fine as Ra 0.2 µm |

| Maximum Cutting Thickness | Up to 12 inches (300 mm) – varies based on material |

| Wire Diameter Range | 0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

Mirror EDM delivers mirror-reflective parts through high precision machining. Capable of producing intricate shapes with tight tolerances, it excels on hard materials where conventional tools falter. Catering to industries from aerospace to electronics, our Mirror EDM ensures unparalleled precision, capturing intricate contours and complex geometries consistently.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Surface Finish | Achievable down to Ra 0.05 µm or better (based on material and process parameters) |

| Tolerance | ± 0.00005 inches (0.0013 mm) or better (depending on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Maximum Cutting Thickness | Up to 10 inches (250 mm) – varies based on material |

RapidDirect’s advanced manufacturing facility features high-precision grinding machines, perfect for manufacturing metal parts with tight tolerances. Our versatile grinding excels from small parts to complex geometries. The precision wheels provide controlled material removal, ensuring polished finishes. This efficiency reduces costs, wear, and errors. Trust our expert team to guide you to the ideal grinding solution for your project.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Ceramics, Carbides |

| Grinding Methods | Surface Grinding, Cylindrical Grinding, Centerless Grinding, Internal Grinding |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (specific to material and grinding method) |

| Maximum Workpiece Size | Length: 24 inches (600 mm) Width: 10 inches (250 mm) Diameter: 8 inches (200 mm) for cylindrical grinding |

| Surface Finish | Achievable down to Ra 0.1 µm or better (based on material and grinding method) |

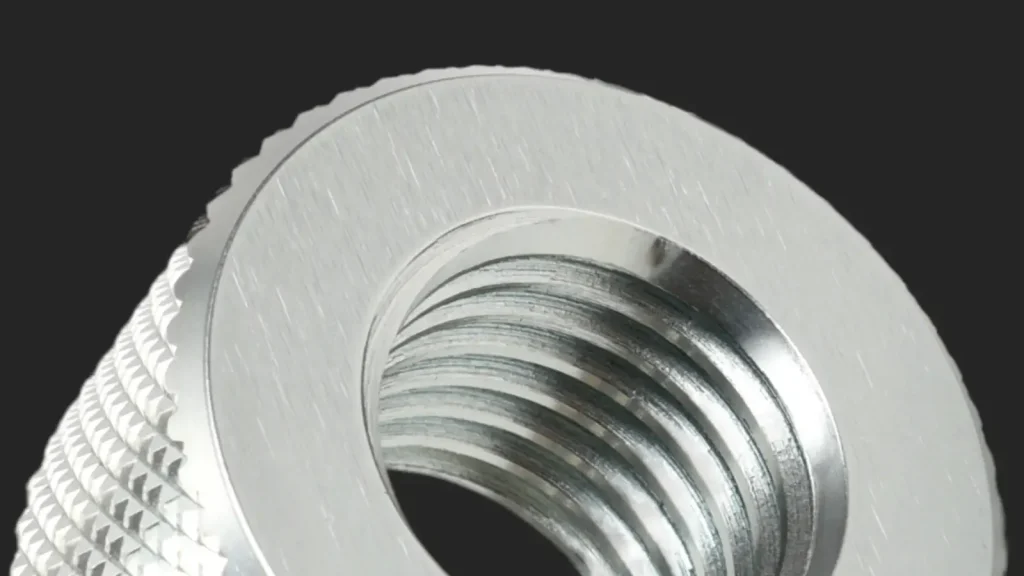

RapidDirect’s advanced CNC turning delivers unmatched accuracy and repeatability for machine parts and prototypes. Our diverse turning centers cater to varied applications, ensuring consistent precision across batches. With reduced errors, we offer quicker production without sacrificing quality. Rely on our technicians and top-grade CNC machines for exceptional component craftsmanship.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Turning Operations | External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Diameter | 20 inches (508 mm) or specific to machine capability |

| Maximum Workpiece Length | 60 inches (1524 mm) or specific to machine capability |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

RapidDirect’s multi-axis milling machines guarantee CNC parts with tight tolerances and precise dimensions. This technology delivers precision tailored to your needs, ideal for iterations and new products. Compatible with a broad material range, from metals to composites, our CNC milling boasts efficiency, having parts ready swiftly.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Milling Operations | Face Milling, Profile Milling, Pocket Milling, Complex Surface Milling, Drilling, Boring |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Size | X: 40 inches (1016 mm) Y: 20 inches (508 mm) Z: 25 inches (635 mm) or specific to machine capacity |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

We offer a wide selection of metals and plastics, each chosen for strength, durability, and precision. Our expert surface finishing options, from anodizing and polishing to powder coating, enhance both the performance and appearance of your parts.Every finish is applied with care to ensure superior quality, protection, and a flawless final look.

We provide a wide range of materials, including metals, plastics, and composites.

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Precision machining is essential when your project demands components with extremely tight tolerances, intricate details, or complex geometries that conventional machining cannot achieve. It is particularly critical for industries like aerospace, medical devices, and electronics. If your parts need to endure high stress, operate under extreme conditions, or fit precisely into assemblies, precision machining ensures reliability, functionality, and consistent performance.

Yes. Precision machining is designed to deliver exceptionally tight tolerances, often as narrow as ±0.0005 inches. This high level of accuracy is crucial for parts where even minor deviations can impact performance, such as in aerospace or medical components. Using advanced CNC machines, precision machining reliably produces consistent, high-quality parts that meet these strict specifications.

To request a quote, provide detailed information about your part or assembly, including CAD drawings, material specifications, quantity, and required tolerances. Specify any additional post-processing, such as surface finishing or heat treatment. Upload your design files to Bluedirect online platform to receive a fast and accurate pricing estimate for your CNC precision machining project.

We perform multi-stage inspections — including incoming material checks, in-process inspections, and final quality verification — using advanced equipment such as CMMs, micrometers, and XRF analyzers.