Get instant quotes and access high-quality sheet metal prototypes and production parts with precision and

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

With a network of over 100 advanced machines, including laser cutters, bending equipment, and welders in our China-based facilities, we can produce sheet metal parts in any quantity — from low-volume prototypes to large-scale production. Our experienced engineers and domestic fabricators ensure precision, quality, and fast delivery for every project.

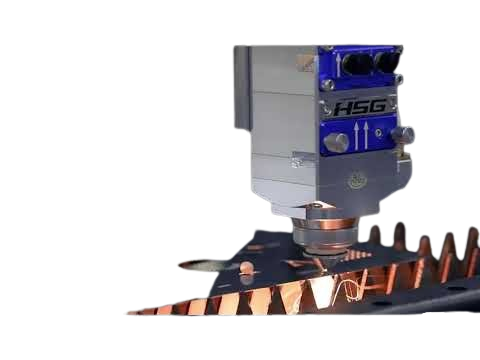

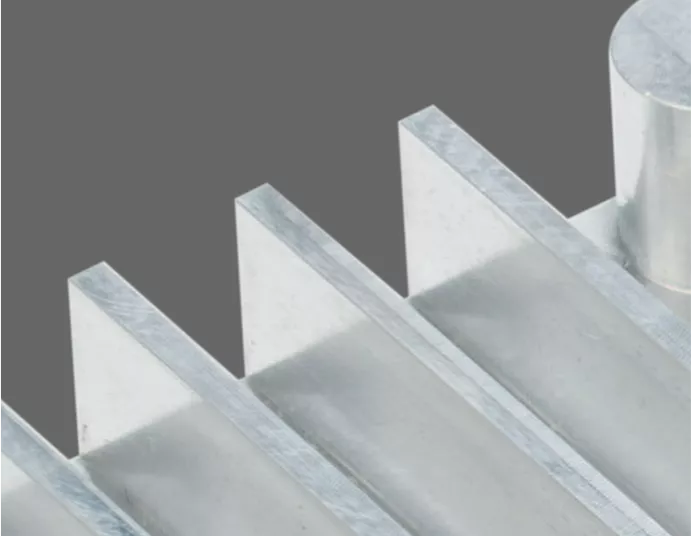

Laser cutting employs a highly focused laser beam to cut, engrave, or etch materials with exceptional precision. It vaporizes or melts the material, producing clean edges and intricate patterns exactly as specified in the design.

Welding is the process of joining two or more metal components using heat, pressure, or a combination of both to create a strong, durable bond. This process requires precision and skill to produce sturdy, long-lasting metal structures.

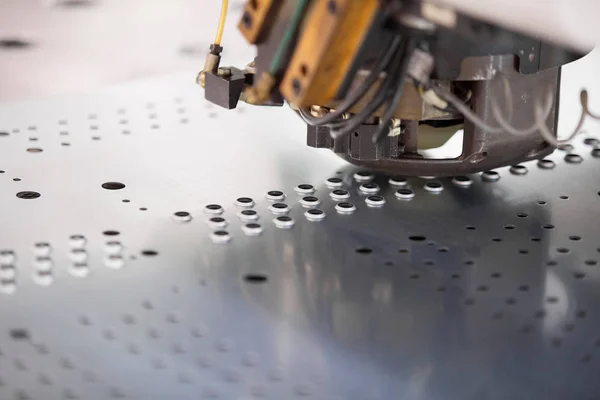

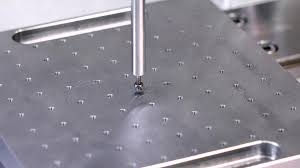

Punching is a process that uses a punch tool and die to cut holes or shapes in metal. The shearing action produces clean, precise cuts, making it ideal for accurate sheet metal fabrication.

Riveting is a semi-permanent joining method that uses mechanical fasteners (rivets) to connect sheet metal parts. It is faster and more cost-effective than welding, making it ideal for efficient fabrication.

Stamping is a process that uses dies and presses to transform flat metal sheets into complex, three-dimensional shapes. This cold-forming technique allows for precise, intricate designs in sheet metal fabrication.

Headquartered in China, Bludeek integrates in-house production with a reliable network of skilled manufacturing partners to deliver high-quality, on-demand solutions. We provide precision machining, molding, and fabrication services with worldwide shipping — reaching clients in North America, Europe, and beyond within 3–10 days. Our experienced, English-speaking engineering team ensures clear communication and efficient project execution across every time zone.

Enhance the strength, corrosion resistance, and visual appeal of your fabricated metal parts with Bludeek’s wide range of finishing solutions. From protective coatings to decorative finishes, we ensure your components meet both functional and aesthetic standards. Need a specific finish? Simply select “Other” and share your requirements with us.

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts..

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

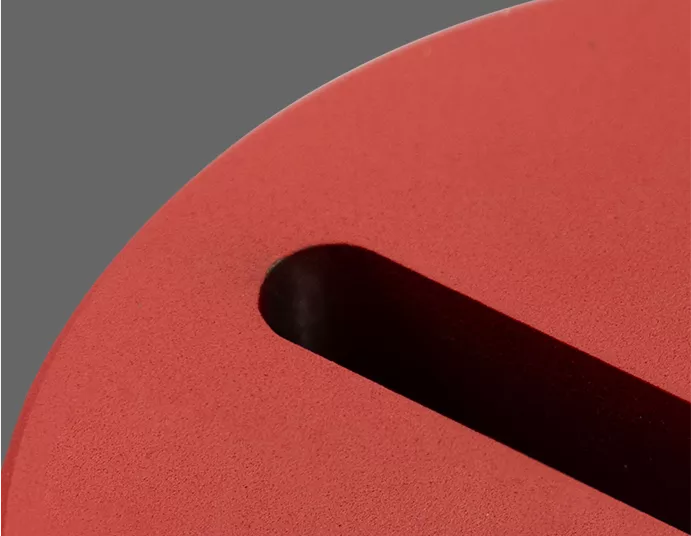

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

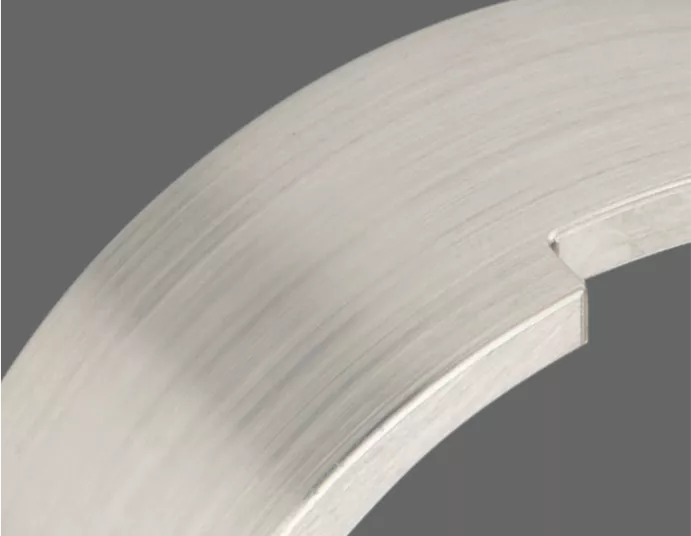

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

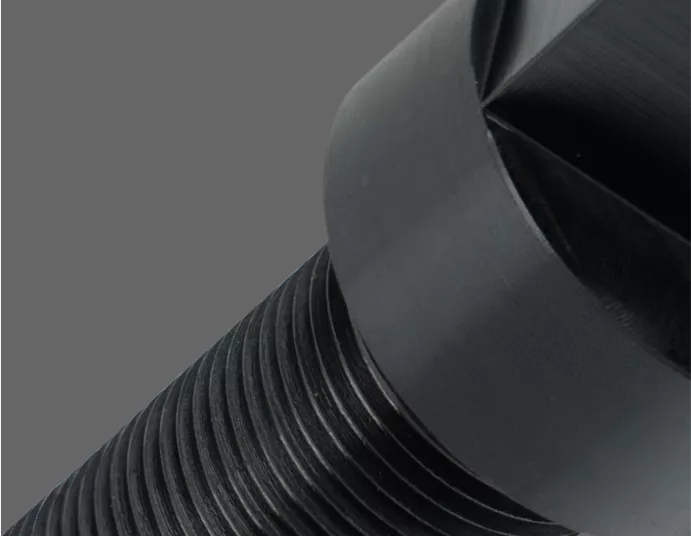

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Receive precision sheet metal prototypes in as fast as 3 business days. Bludeek’s rapid prototyping service supports quick design testing, functional validation, and cost-efficient product development — all with no minimum order requirement.

Quantity: 1–50 pcs

Lead Time: 3–7 days

Our low-volume sheet metal service is ideal for small batch production before mass manufacturing. We deliver precise parts quickly with consistent quality—perfect for testing, limited runs, or custom needs.

Quantity: 50–5000 pcs

Lead Time: 1–3 weeksOur

Our high-capacity sheet metal fabrication ensures efficient, precise large-scale production. With integrated finishing and assembly, we deliver consistent quality, faster turnaround, and cost-effective results for 5,000+ parts.

Quantity: 5,000+ pcs

Lead Time: 4–8 weeks

At Bludeek, we prioritize precision and quality at every stage of sheet metal fabrication — from concept to final production. Our team applies Design for Manufacturability (DFM) principles, ensuring each project is optimized for performance, cost, and efficiency.

We use advanced, computer-controlled technologies like laser cutting, bending, punching, welding, stamping, and riveting to create accurate, high-quality components. Every part undergoes thorough inspection using CMMs, XRF analyzers, gauges, micrometers, and calipers to ensure exact tolerances and flawless results.

With extensive industry experience and ISO-certified facilities, Bludeek guarantees dependable, high-performance sheet metal solutions tailored to your specifications.

Simply provide your CAD files or detailed design specifications. Our engineers will review your design, provide DFM (Design for Manufacturability) feedback, and give you a quote to begin production.

Lead times vary by order size:

Rapid Prototyping: 3–7 days for 1–50 pcs

Low-Volume Fabrication: 1–3 weeks for 50–5,000 pcs

High-Volume Production: 4–8 weeks for 5,000+ pcs

Costs depend on factors like material, thickness, complexity, quantity, and finishing. Contact our team with your design for an accurate, instant quote.

The K factor represents the ratio of the neutral axis to the material thickness during bending. It helps calculate accurate bend allowances and ensures precise part dimensions.

Sheet metal is thinner (usually <6 mm) and easier to bend or form, suitable for enclosures, panels, and components. Plate metal is thicker (>6 mm), stronger, and mainly used for structural parts.