Achieve unmatched precision and intricacy with our Wire EDM machining solutions. Perfect for complex geometries and demanding applications, Bludeek’s experienced team delivers parts that meet the highest standards of accuracy and quality. ISO-certified facilities guarantee repeatable results and reliability for every project.

As an ISO-certified company, our standard tolerances are defined by ISO 2768 standards. We offer a range of injection mold tooling tolerances to meet your requirements. Based on your design, we can reach tight tolerances up to +/-0.02mm.

We guarantee quick turnarounds with streamlined processes and designated assembly areas, guaranteeing that your products are delivered on time without sacrificing quality.

Take advantage of Bludeek’s knowledgeable specialists, who combine extensive expertise, rigorous training, and the newest techniques to provide unmatched assembly quality.

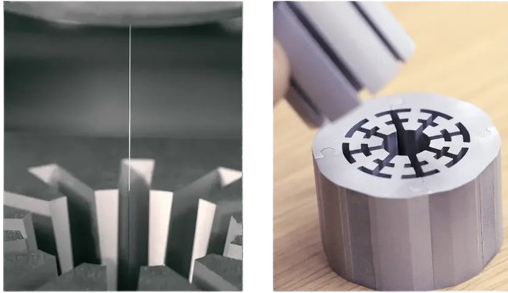

At Bludeek, we leverage Wire Electrical Discharge Machining (EDM) to produce precision-engineered metal components with unmatched accuracy. Wire EDM is a specialized process that uses controlled electrical discharges between electrodes in a dielectric fluid to cut intricate shapes and fine details by melting and vaporizing the metal.

This technology excels at machining complex contours and tiny features in materials that are difficult to process with traditional CNC methods, including heat-treated steels, superalloys, and other specialty metals. With Wire EDM, we achieve extremely tight tolerances and precise details such as narrow slots, fine holes, and intricate profiles.

Our services are ideal for applications demanding the highest level of precision, from aerospace and automotive components to molds, dies, and specialized industrial parts. Backed by advanced Wire EDM equipment and a team of skilled technicians, Bludeek ensures every part is manufactured to the strictest quality standards, delivering reliable, consistent, and high-performance results for even the most challenging projects.

Wire EDM machining combines precision and versatility, enabling the production of intricate metal components with exceptional accuracy across a wide range of industries.

Wire EDM provides unmatched precision and flexibility for high-accuracy machining:

EDM machining includes Wire EDM, which uses a thin wire to cut metal, and Sinker EDM, which employs an electrode to create cavities or complex shapes in conductive materials.

Yes, Wire EDM can cut any electrically conductive material, including hard metals like titanium, hardened steel, and superalloys, without causing stress or deformation.

Wire EDM is extremely precise, capable of achieving tolerances as tight as ±0.0001 inches, making it ideal for high-accuracy applications.

Wire EDM can cut thick materials, though cutting speed may decrease as thickness increases. Specialized setups allow machining of relatively large sections with high precision.

Wire EDM can only cut electrically conductive materials. It is generally slower than conventional machining for simple cuts and is less suitable for very high-volume production of simple parts.